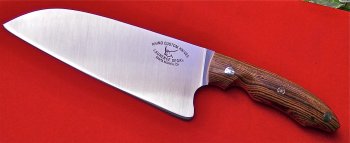

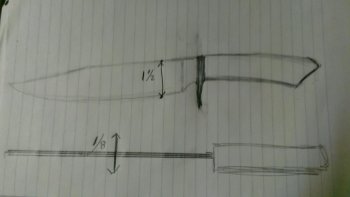

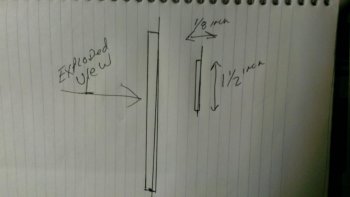

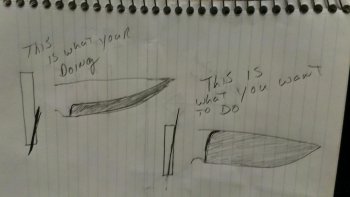

I'm a new guy in knife making. One of my biggest challenges is to have a nice deep grind. With 5/32" blade stock and a blade 1 1/8" wide. If I want my grind 1" tall, I find it takes a lot of practice to get a clean straight grind line. The less of an angle/ taller grind line, the tougher it is to keep from washing out your desired grind line. It is for sure possible to do, I've seen lots of makers do it all the time, but it's possible to learn. Would be easier with a jig, but I suspect you are free hand grinding like I do. Practice practice practice