Smallshop

KNIFE MAKER

So I started out trying to engrave A2 tool steel on my cnc machine...no dice. Tried it on heat treated next...maybe the steel won't be as gummy. Yeah...dope...lol

Meanwhile them tiny endmills are expensive...$11-20...coated with unicorn poo makes 'em better ...supposedly...definitely more expensive. And they are quickly adding up in my little 'research' project....

So I build an etcher...finished it yesterday....first etch....meh. BUT the realization...!!

THIS WILL TAKE TECHNIQUE!!! (meaning training someone...or not)

So ted will be the only guy grinding blades and marking blades? no...no way.

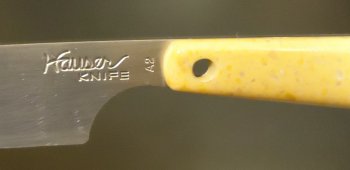

So back to the CNC this morning....after the ah-HAH moment... where I realized that just MAYBE I could use a carbide dremel tool to engrave? Yep...they cost $5.83...maybe less if I shop them out...and the results are beautiful! (well...I think so...)

I actually think I'm too deep which is a nice feeling...the endmills never got deep enough before they snapped like pretzel sticks during a super bowl game....

Meanwhile them tiny endmills are expensive...$11-20...coated with unicorn poo makes 'em better ...supposedly...definitely more expensive. And they are quickly adding up in my little 'research' project....

So I build an etcher...finished it yesterday....first etch....meh. BUT the realization...!!

THIS WILL TAKE TECHNIQUE!!! (meaning training someone...or not)

So ted will be the only guy grinding blades and marking blades? no...no way.

So back to the CNC this morning....after the ah-HAH moment... where I realized that just MAYBE I could use a carbide dremel tool to engrave? Yep...they cost $5.83...maybe less if I shop them out...and the results are beautiful! (well...I think so...)

I actually think I'm too deep which is a nice feeling...the endmills never got deep enough before they snapped like pretzel sticks during a super bowl game....

Last edited: