Ty Adams

KNIFE MAKER

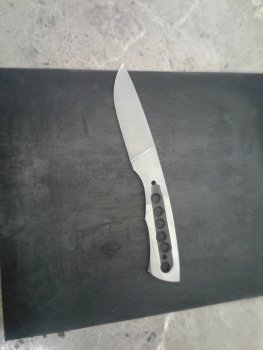

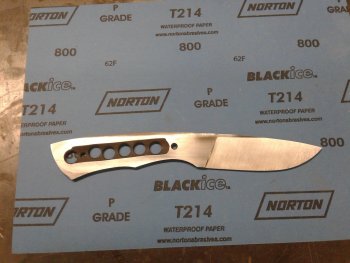

I want to participate in the Kith but as always work has me working more hours then I want. So I'm going to pull out a knife that was started some time ago. If it can go wrong it went wrong on this knife. So I'm going to try and save it for the Kith. This may work! It also might be a big flop, the benefit will be pass or fail, new things will be learned.

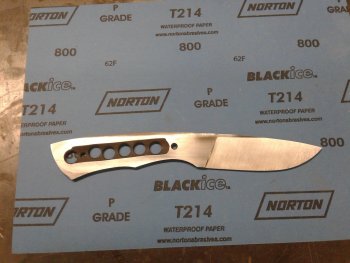

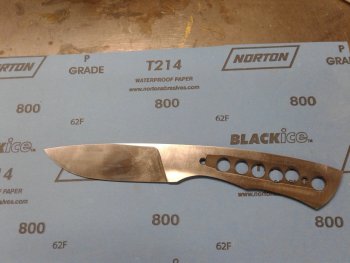

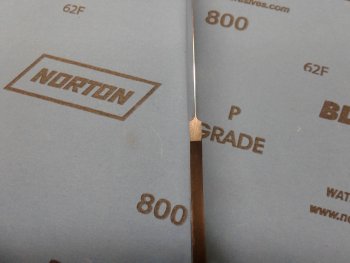

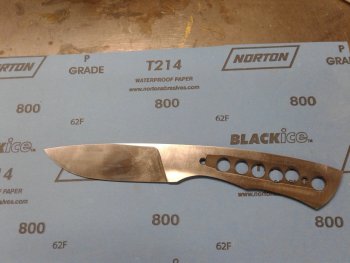

To start I'll point out what needs to be fixed. While post heat treat grinding a 120 grit belt tore and left a gouge in the plunge line on the left side.

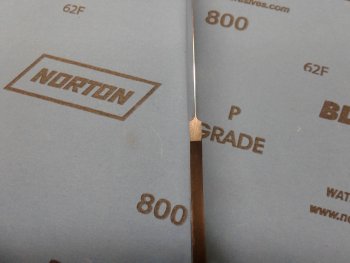

The right hand side of the knife had a much worse fate... I sneezed while grinding. This left a gouge that went passed the spine. While trying to fix the mistake there is a spot in the belly of the blade is slightly thinner the rest of the blade.

Fixing the grind that went all the passed the spine made it so that I had to thin the blade out some, and the plunge lines, and grind lines don't match.

These are all things that can be over come with some elbow grease and patients. As I get time I'll update the thread and hopefully have a knife to contribute to the Kith.

To start I'll point out what needs to be fixed. While post heat treat grinding a 120 grit belt tore and left a gouge in the plunge line on the left side.

The right hand side of the knife had a much worse fate... I sneezed while grinding. This left a gouge that went passed the spine. While trying to fix the mistake there is a spot in the belly of the blade is slightly thinner the rest of the blade.

Fixing the grind that went all the passed the spine made it so that I had to thin the blade out some, and the plunge lines, and grind lines don't match.

These are all things that can be over come with some elbow grease and patients. As I get time I'll update the thread and hopefully have a knife to contribute to the Kith.