Mark Barone

Well-Known Member

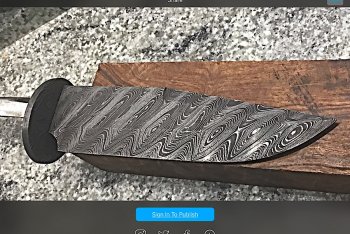

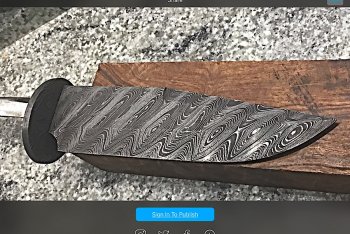

This has been tough for me, but I am following the rules By at least doing the best I can. It’s a Gents Bowieish design , OAL will probably be about 11 inches. I opted not to do the clip point. I couldn’t get the wedge down. It’s Alabama Damascus. Heat treated and final sanding before acid etch was 600 grit. 50/50 Ferric and Apple Cider Vinegar for 45 minutes. Then lightly sanded with 1000 grit. I think I will go with this iron wood for the handle.

Something about the guard doesn’t seem right. Maybe because the handle is not on it yet. I wanted it to be a little more of a narrow oval, but then it seemed like the handle would be too thin. Right now the guard 7/8 inch wide at the center of the oval. It’s also Damascus. Maybe I should do some file work around the guard. Any comments or advice, critical or not always appreciated.

Something about the guard doesn’t seem right. Maybe because the handle is not on it yet. I wanted it to be a little more of a narrow oval, but then it seemed like the handle would be too thin. Right now the guard 7/8 inch wide at the center of the oval. It’s also Damascus. Maybe I should do some file work around the guard. Any comments or advice, critical or not always appreciated.