John Wilson

Well-Known Member

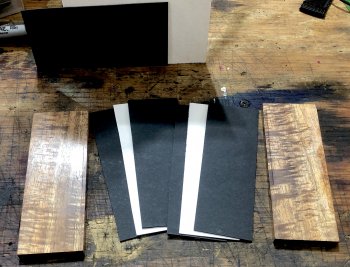

Started on the KITH for Johan.

This will be an 8” Chef in Koa with black and white liners. Kitchen knives are measured by the length of the blade. This knife has a cutting edge of about 8-1/4 inches (210mm). It will be 2” tall at the heel (~ 50mm). I am starting with .110” thickness which will end up with a full length taper from near the butt of the handle to the tip. The thickness of the spine at the heel (the front of the handle) will be approximately 2mm. The blade will be in the Japanese style of a Gyuto, which is based on the French Chef knife, but without bolsters or plunges. It will have a Western handle made from Koa (from our own Gene M.)

I believe this style of knife is the best of both worlds. You get the all-around usability of the French Chef pattern (shallow belly which sweeps up to the tip and nearly flattens toward the last 1/3 of the blade, which is fantastic for chopping) but with the thin plungeless, bolsterless light weight of the Japanese style knife which makes it a slicing hot rod of a performer. The Western handle feels more at home in the hand for those of us who grew up on western contour handles, and is also heavier to provide a great counterbalance for rocking and doing fine work on the board with the tip. The balance being just forward of the handle makes for a very fast and very controllable knife.

I will round the spine and the heel. This makes for an extremely comfortable knife when choking up on the blade in a pinch grip.

This will be an 8” Chef in Koa with black and white liners. Kitchen knives are measured by the length of the blade. This knife has a cutting edge of about 8-1/4 inches (210mm). It will be 2” tall at the heel (~ 50mm). I am starting with .110” thickness which will end up with a full length taper from near the butt of the handle to the tip. The thickness of the spine at the heel (the front of the handle) will be approximately 2mm. The blade will be in the Japanese style of a Gyuto, which is based on the French Chef knife, but without bolsters or plunges. It will have a Western handle made from Koa (from our own Gene M.)

I believe this style of knife is the best of both worlds. You get the all-around usability of the French Chef pattern (shallow belly which sweeps up to the tip and nearly flattens toward the last 1/3 of the blade, which is fantastic for chopping) but with the thin plungeless, bolsterless light weight of the Japanese style knife which makes it a slicing hot rod of a performer. The Western handle feels more at home in the hand for those of us who grew up on western contour handles, and is also heavier to provide a great counterbalance for rocking and doing fine work on the board with the tip. The balance being just forward of the handle makes for a very fast and very controllable knife.

I will round the spine and the heel. This makes for an extremely comfortable knife when choking up on the blade in a pinch grip.