JPSWorks

Well-Known Member

I hate to be a downer, but here it goes.

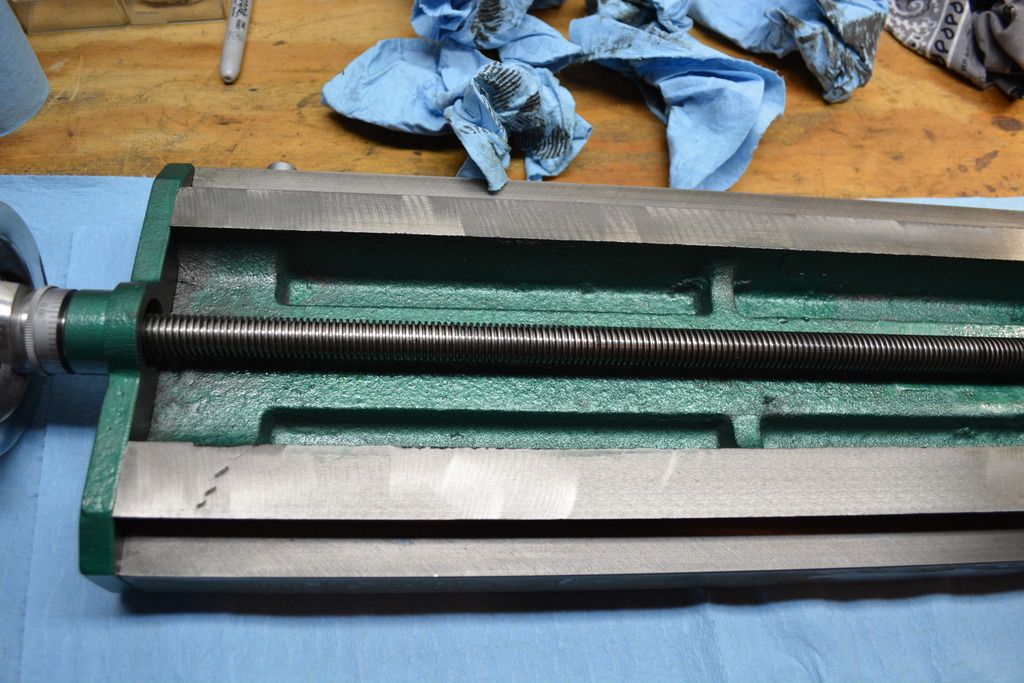

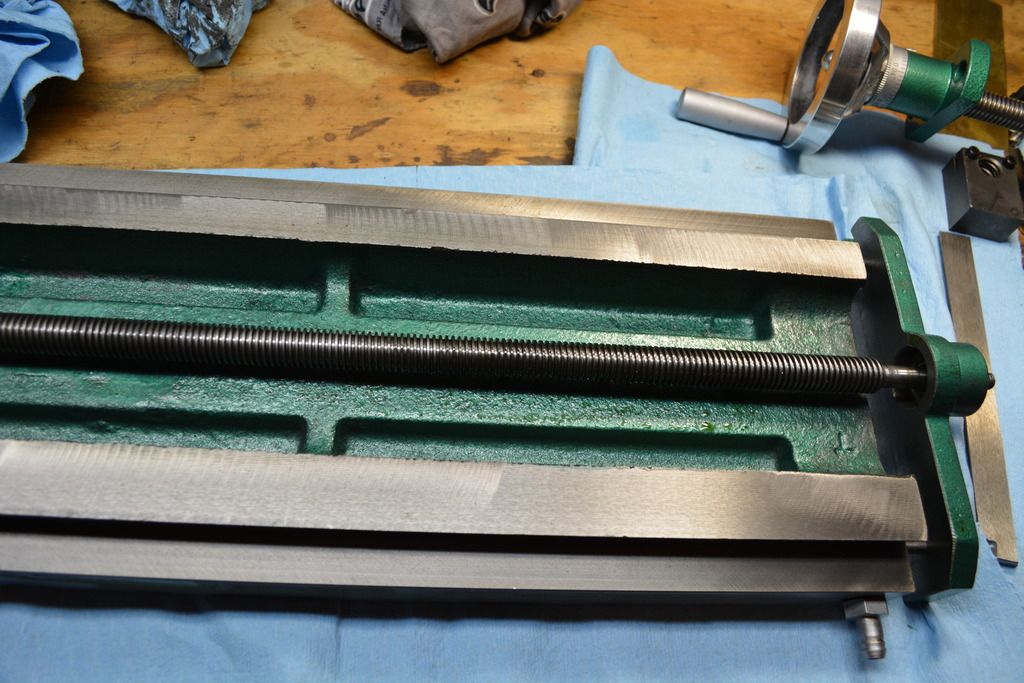

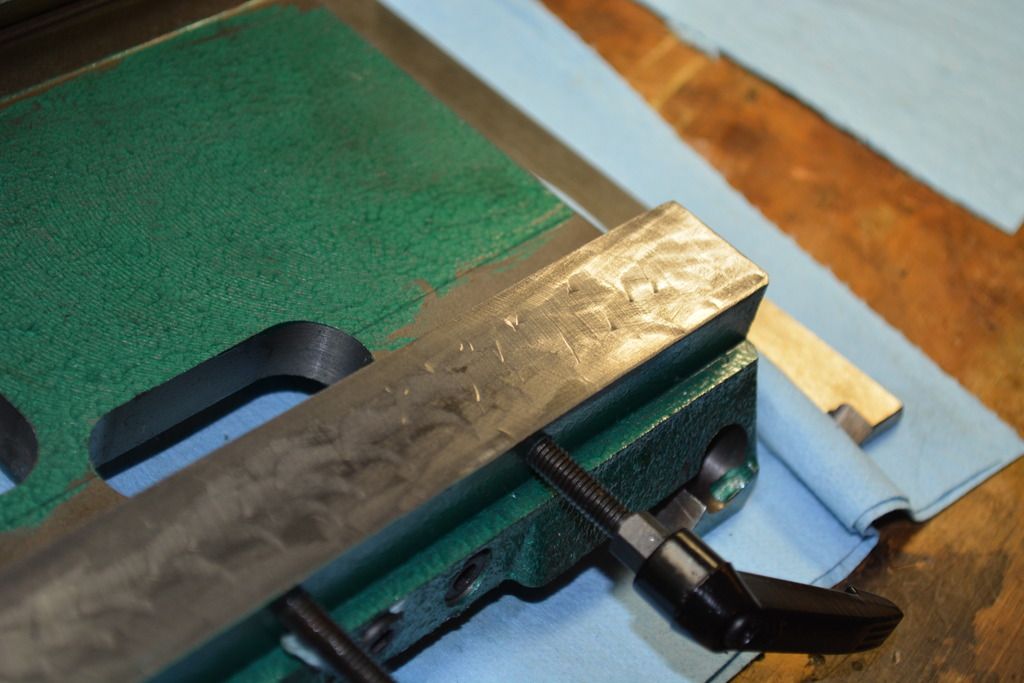

Finally got a chance to work on disassembling the G0704 mill to get rid of all of the shipping grease and check out the quality of the ways. I have to be honest; I am very disappointed with what I received. I fully realize that I didn’t spend $8,000 on a mill, but I expected to get a lot better than this.

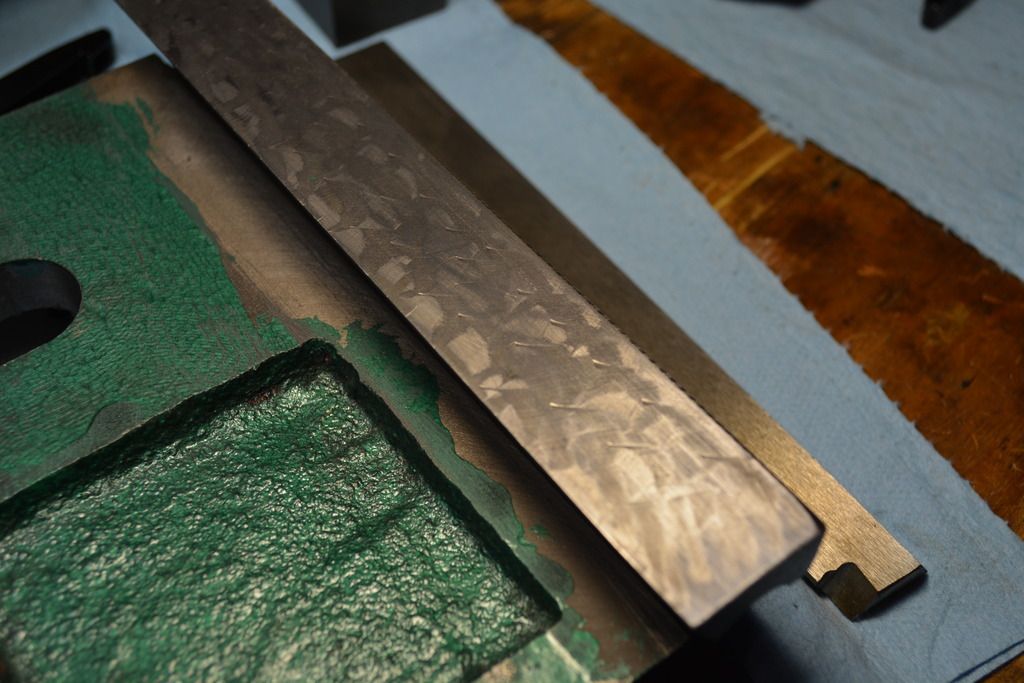

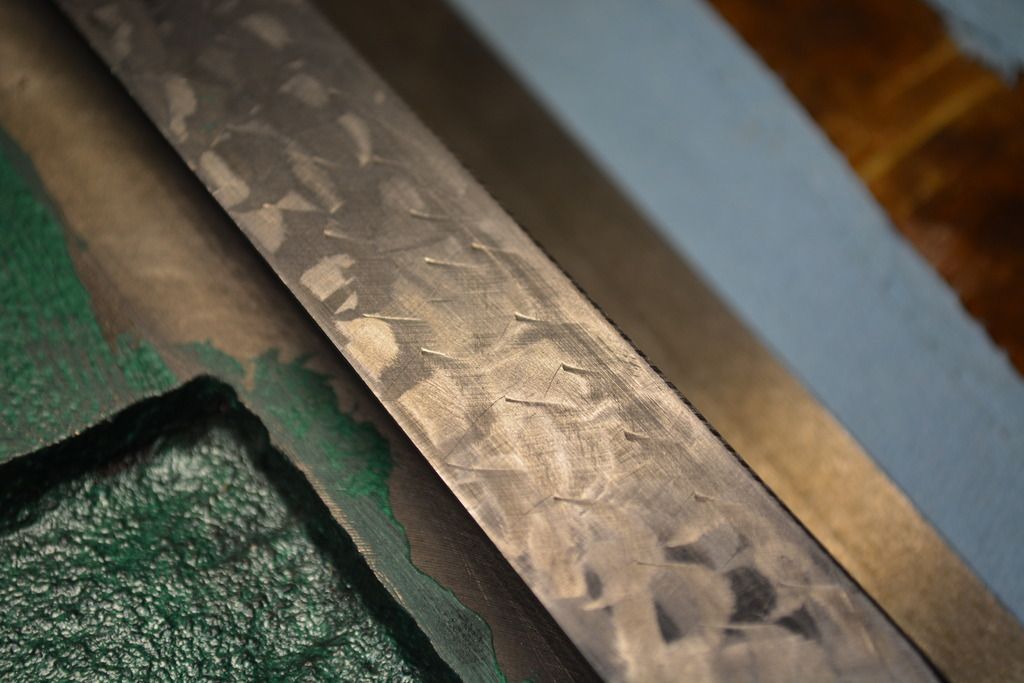

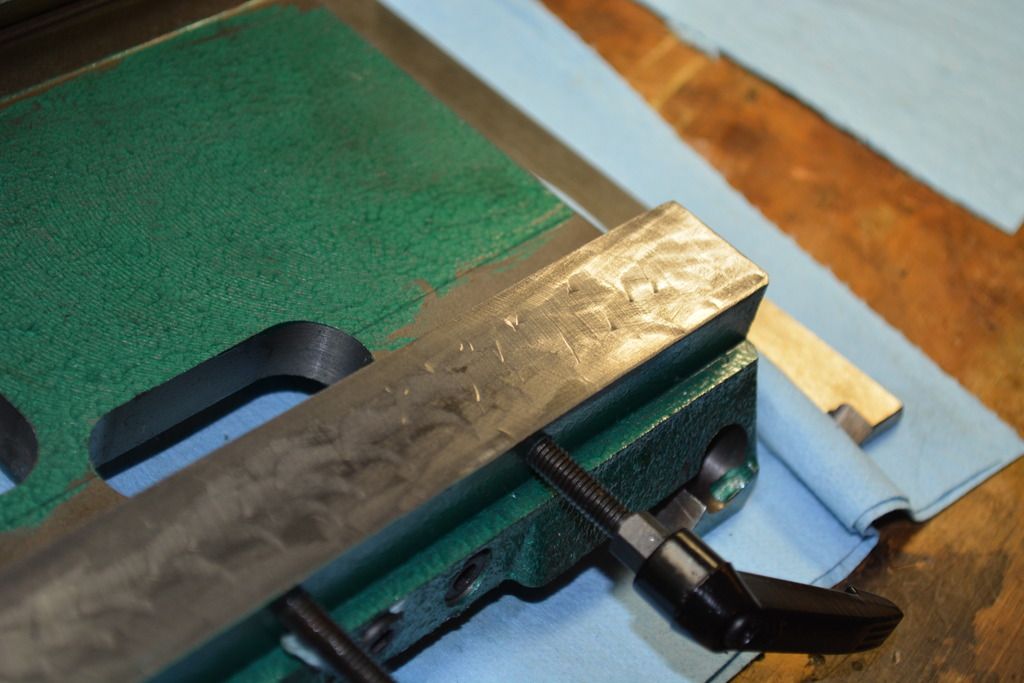

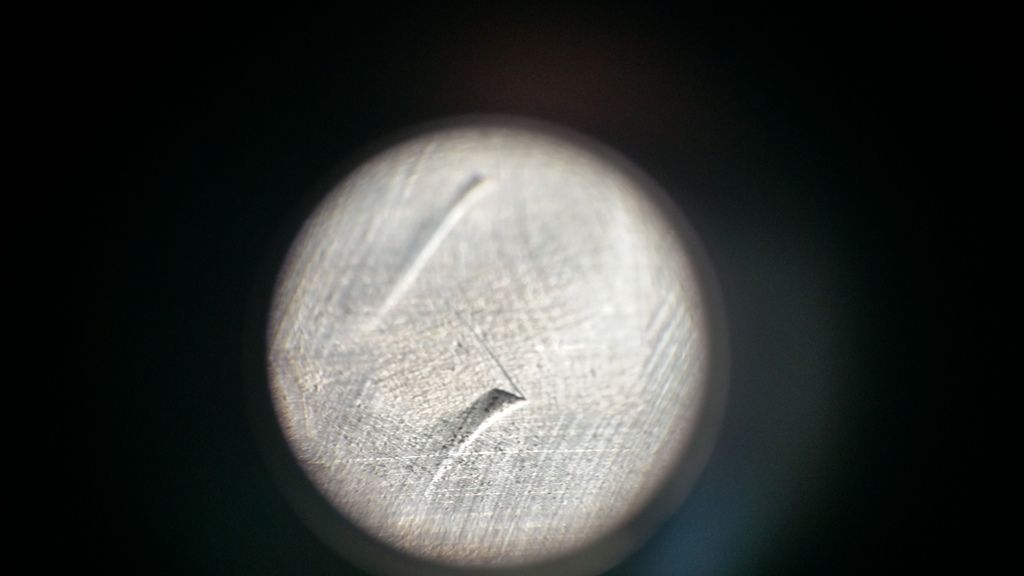

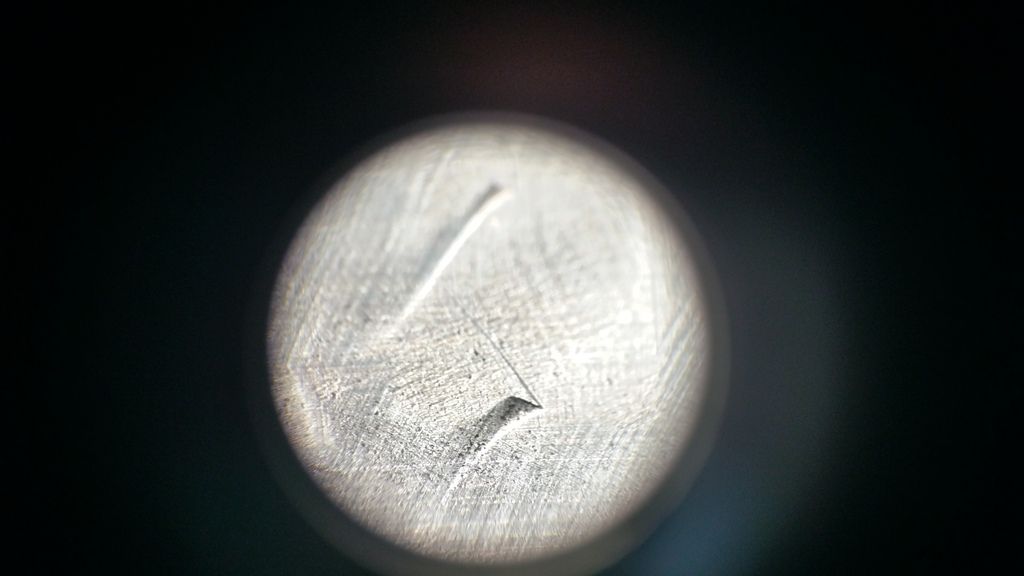

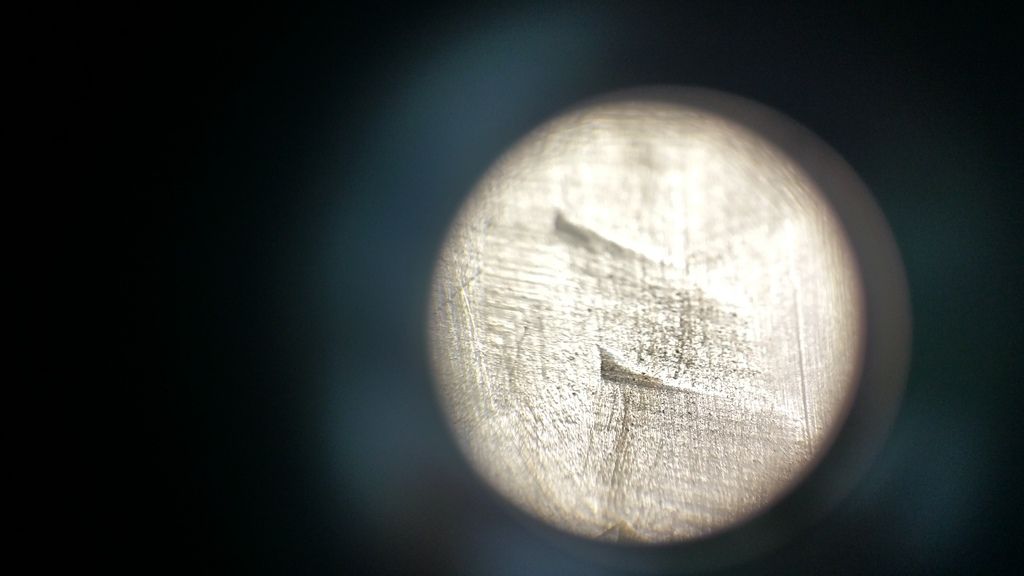

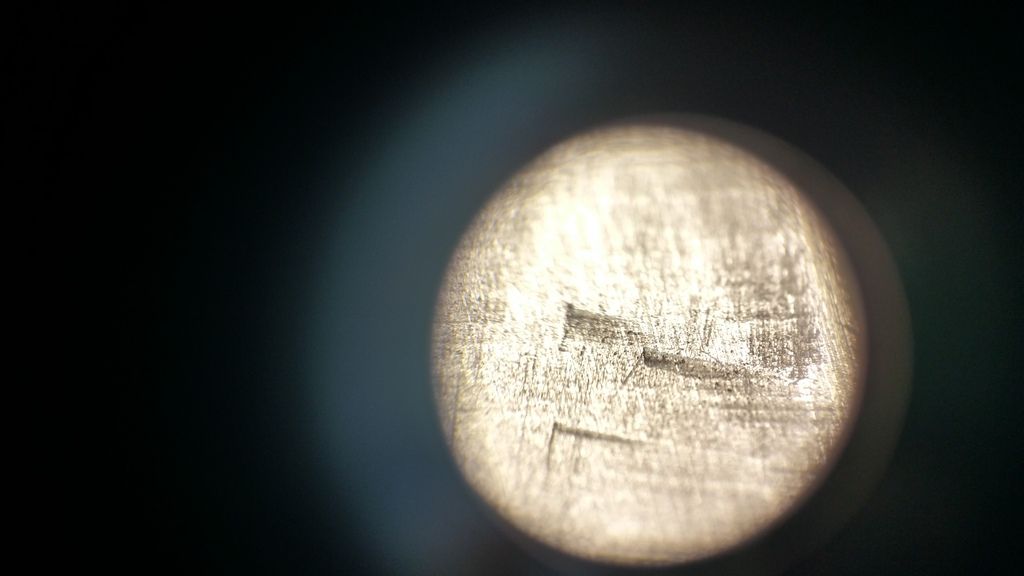

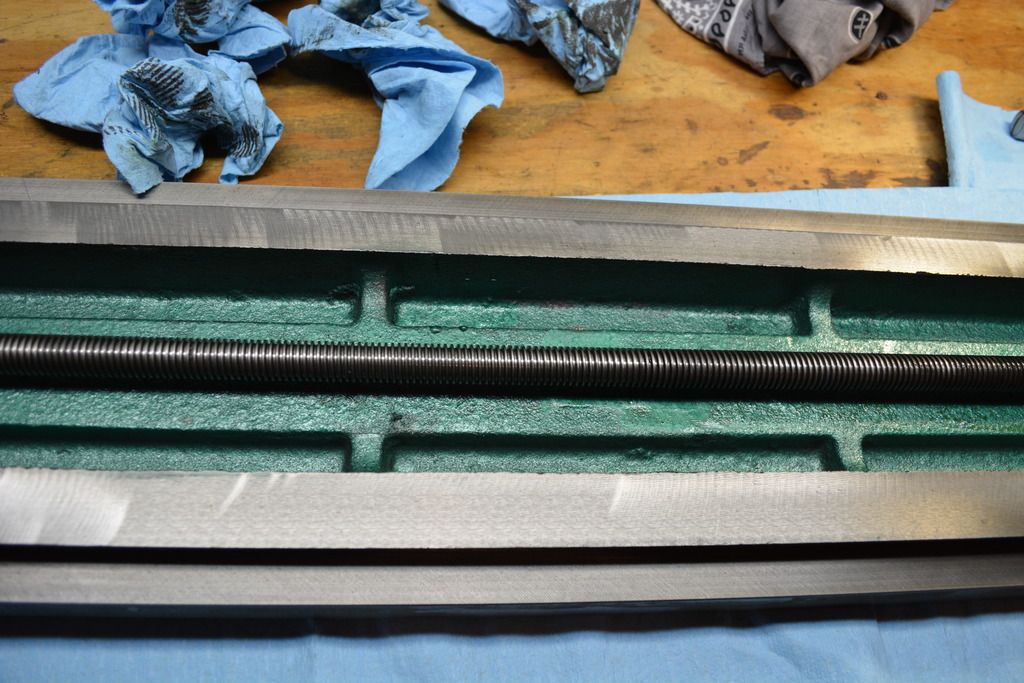

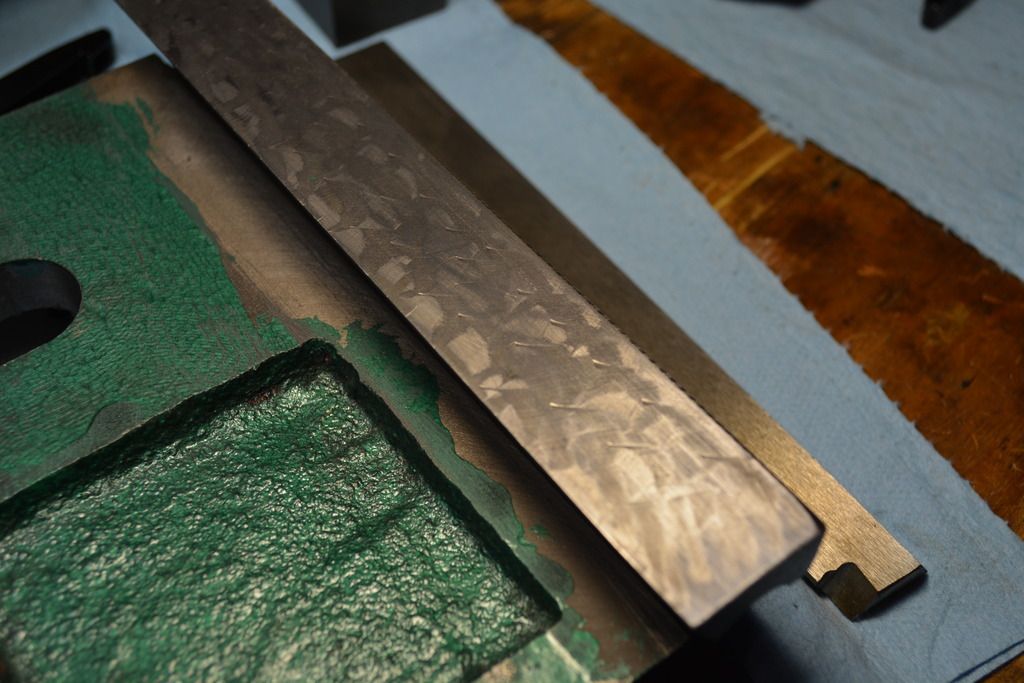

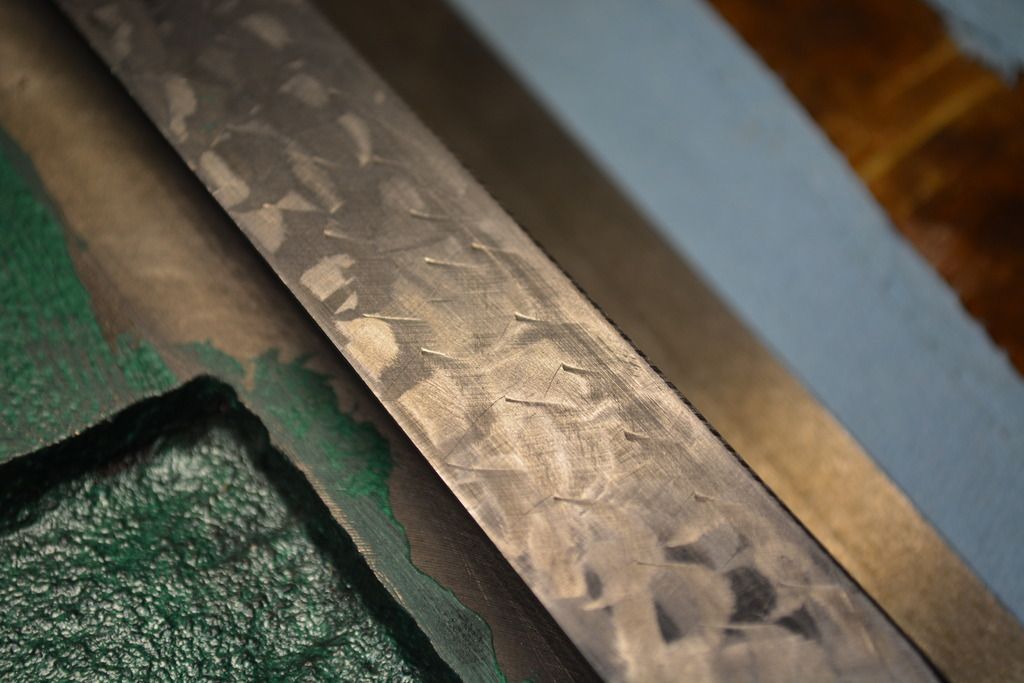

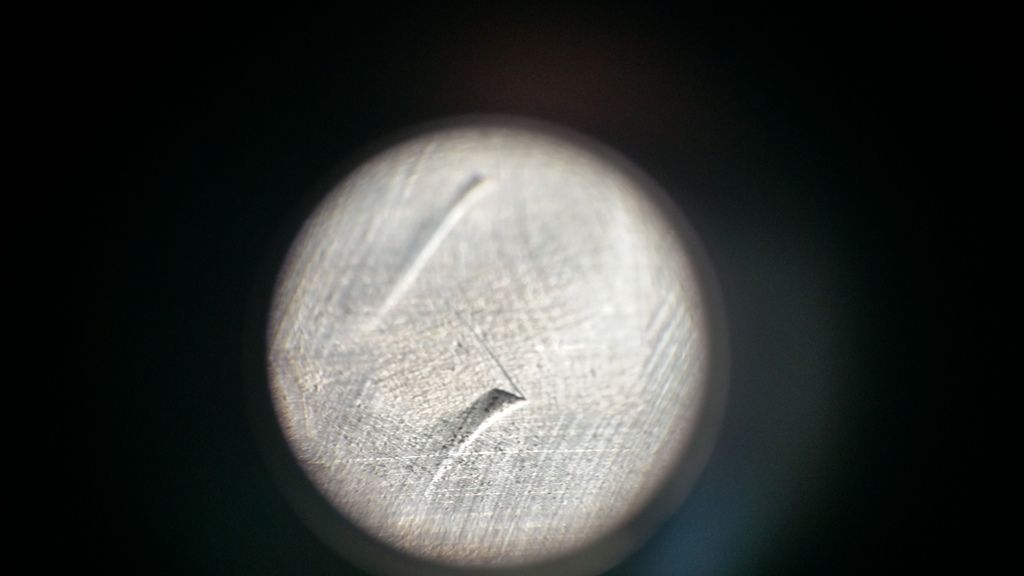

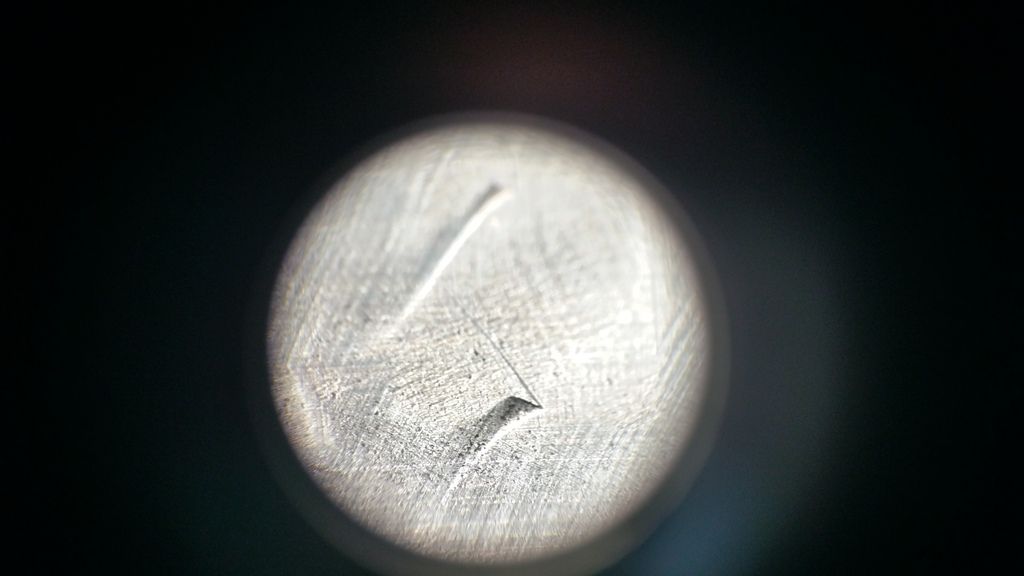

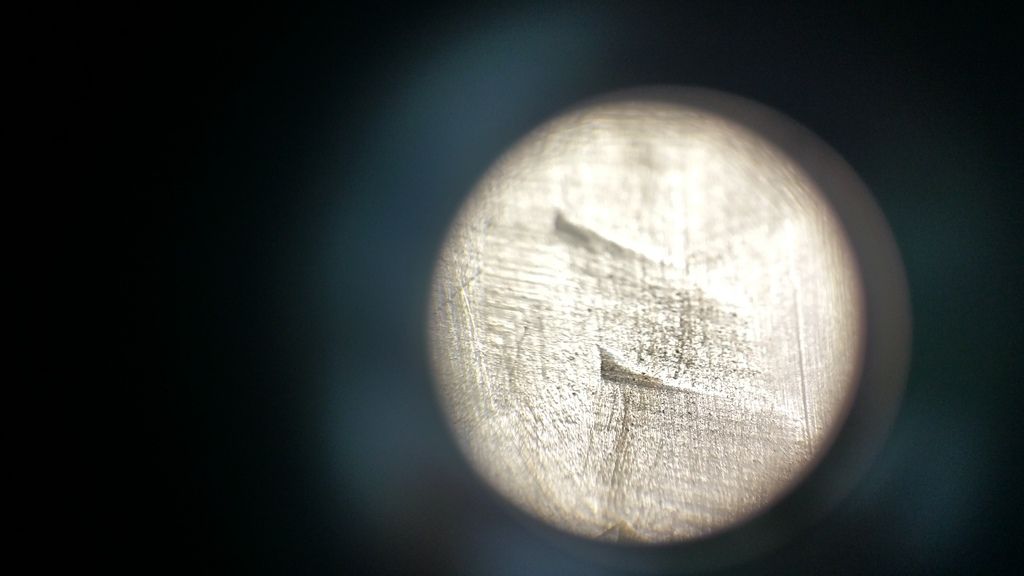

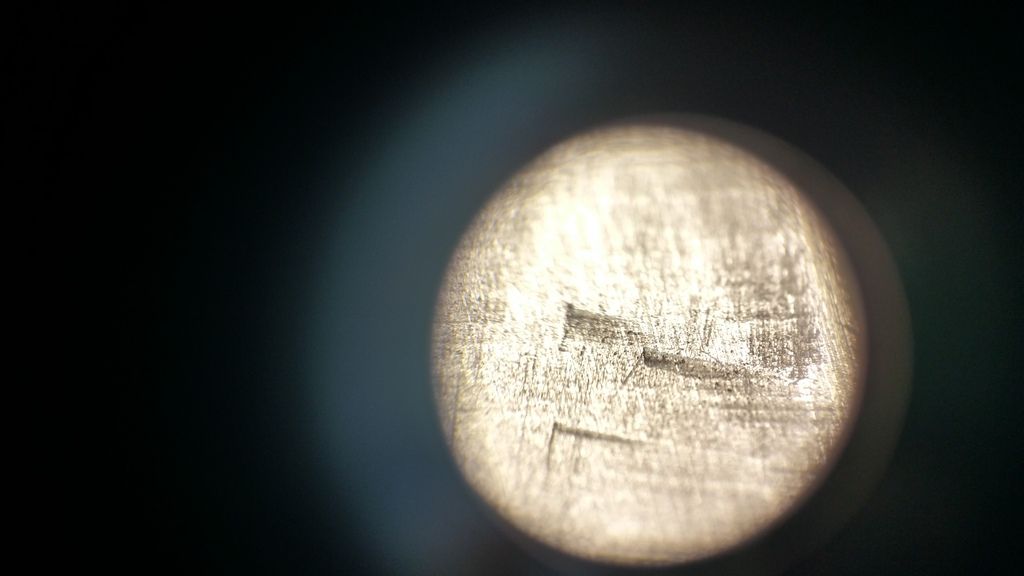

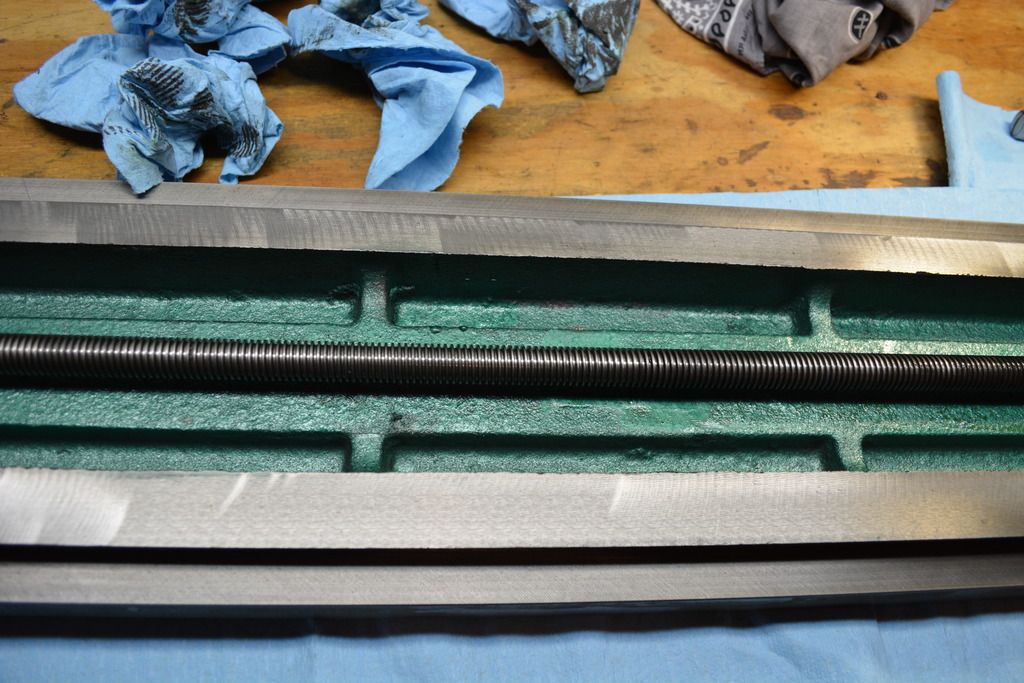

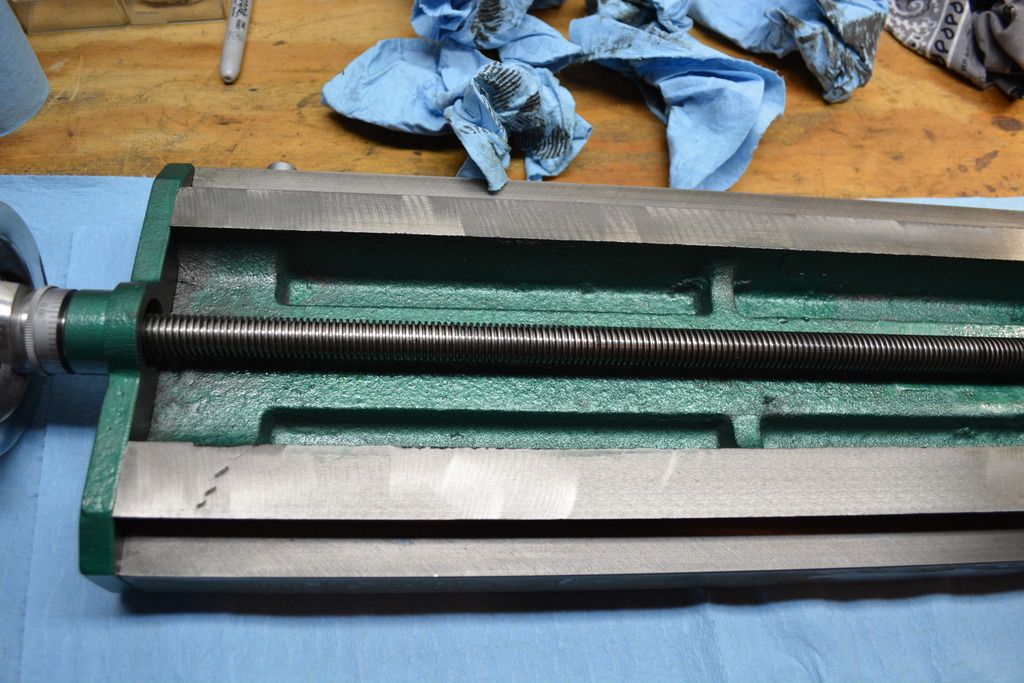

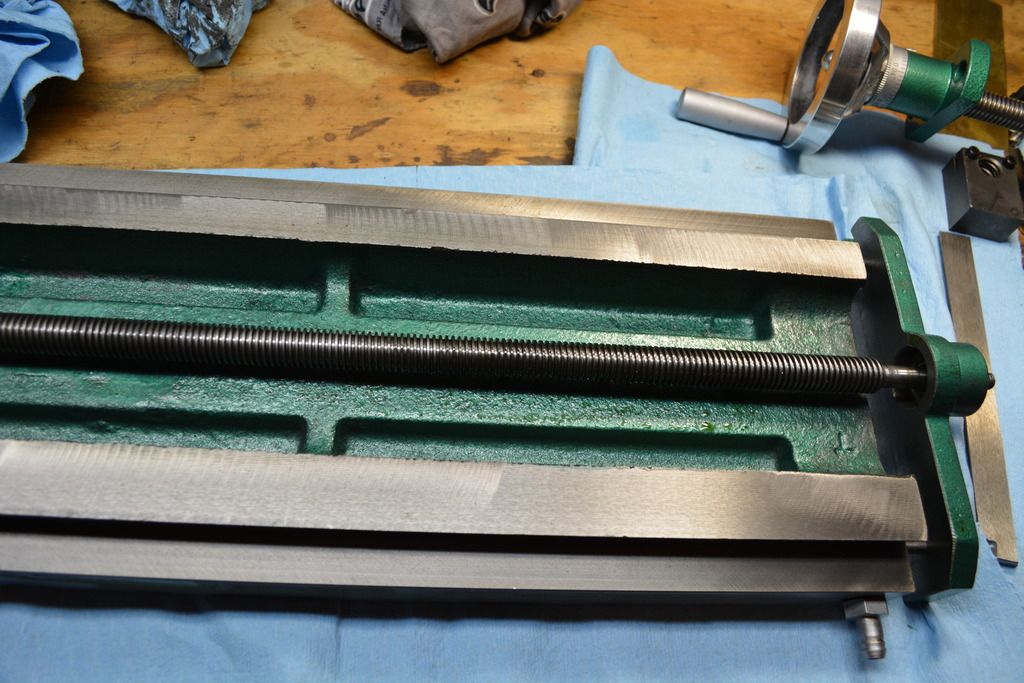

The main issue is with the horrible machining done on the ways, both on the top and the bottom of the saddle. The ways on the table are also not exactly top notch but nowhere near the poor quality level of the saddle. In fact the ways on the saddle look like they were machined with a cutter on its way out. They not only look like awful, they have these gashes/divots all over them that looks like the cutter was uneven and possibly skipping when they were being milled. You can catch your fingernail in each of the divots, let alone feel all the imperfections with the tips of your fingers. Did anyone else experience anything like this with their G0704?

Upon speaking with a couple of other G0704 owners online they all recommended that I contact Grizzly tomorrow morning and ask to have the saddle replaced. The sad thing is that I would have never seen this if I wasn’t so OCD that I had to make sure it was completely free of that nasty grease, so that I could use proper way oil on everything.

I guess on a positive note, the top of the table looks perfect. J

Posting a lot of pics below to try to show the machining and they are a lot worse than the pics look. I also took some crappy close up pics in which I used a 10x loupe held to the camera lens on my phone. But I think they get the point across. Hope that Grizzly works with me on this.

John

68 P0704068 SADDLE

Finally got a chance to work on disassembling the G0704 mill to get rid of all of the shipping grease and check out the quality of the ways. I have to be honest; I am very disappointed with what I received. I fully realize that I didn’t spend $8,000 on a mill, but I expected to get a lot better than this.

The main issue is with the horrible machining done on the ways, both on the top and the bottom of the saddle. The ways on the table are also not exactly top notch but nowhere near the poor quality level of the saddle. In fact the ways on the saddle look like they were machined with a cutter on its way out. They not only look like awful, they have these gashes/divots all over them that looks like the cutter was uneven and possibly skipping when they were being milled. You can catch your fingernail in each of the divots, let alone feel all the imperfections with the tips of your fingers. Did anyone else experience anything like this with their G0704?

Upon speaking with a couple of other G0704 owners online they all recommended that I contact Grizzly tomorrow morning and ask to have the saddle replaced. The sad thing is that I would have never seen this if I wasn’t so OCD that I had to make sure it was completely free of that nasty grease, so that I could use proper way oil on everything.

I guess on a positive note, the top of the table looks perfect. J

Posting a lot of pics below to try to show the machining and they are a lot worse than the pics look. I also took some crappy close up pics in which I used a 10x loupe held to the camera lens on my phone. But I think they get the point across. Hope that Grizzly works with me on this.

John

68 P0704068 SADDLE