CDHumiston

KNIFE MAKER

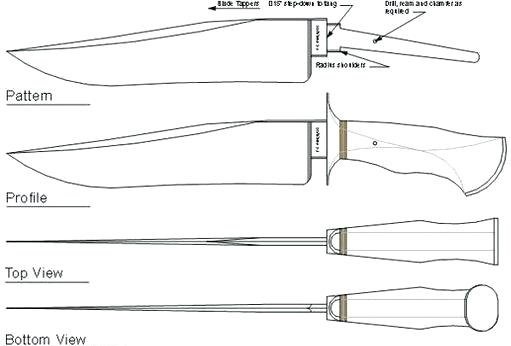

I'm working on this Bowie knife. It's nearly 1/4" thick 440C Stainless. It's my first try at a knife this big and also my first Bowie.

My main question is...what thickness should the blade be near the edge? I've read some people leave it around .040. Looking for help from experienced folks.

Here are a few pics of where I'm at right now.

My main question is...what thickness should the blade be near the edge? I've read some people leave it around .040. Looking for help from experienced folks.

Here are a few pics of where I'm at right now.