You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Felt Platen Duro

- Thread starter Gliden07

- Start date

52 Ford

Well-Known Member

The Boss has spoken. No felt.

Here's an idea, if you want to hear it:

I have a Porter Cable belt sander that has a piece of thin shim stock covering the platen and a soft material behind it to give it some give. If you do this, make sure you're using hardened shims.

Here's a link to 1095 shims on McMaster: https://www.mcmaster.com/Shim-Stock...um-hardness~rockwell-c48/shape~sheet-and-bar/

The leading edge of the spring steel is attached to the platen with screws. There's a step bent into the spring steel to get the screw heads out of the way.

I can take a picture if you want.

Sent from my Champion Forge using Tapatalk

Here's an idea, if you want to hear it:

I have a Porter Cable belt sander that has a piece of thin shim stock covering the platen and a soft material behind it to give it some give. If you do this, make sure you're using hardened shims.

Here's a link to 1095 shims on McMaster: https://www.mcmaster.com/Shim-Stock...um-hardness~rockwell-c48/shape~sheet-and-bar/

The leading edge of the spring steel is attached to the platen with screws. There's a step bent into the spring steel to get the screw heads out of the way.

I can take a picture if you want.

Sent from my Champion Forge using Tapatalk

Gliden07

Well-Known Member

I have a glass platen liner I'm looking for it to help me grind convex blade edges on kitchen knives. I can't afford a rotary platen so figured I'd try a soft platen?Do not use felt as a belt backer.

There are multiple reasons: It wears super fast but most important you can not get a straight grind line using a soft belt back surface.

Research a glass platen instead.

I used to have a rotary platen and want to get one again, but they are expensive. Maybe next year. When I had the KMG rotary platen, I only really used one of the areas (the 2nd shortest gap area) and had to be careful of the belt cupping when grinding and putting a nasty 2" groove in the blade. With a tall kitchen knife, I had to be careful not to have the spine on the roller itself, so a 3-4" wide area between the rollers would be nice IMHO. Maybe BossDog can put together a kit that we can assemble with a ~4" gap between 2 rollers? Having 4 rollers is $200 alone in just rollers, so a 2 roller rotary platen may be more cost effective?

S2-32 Felt from McMaster-Carr has very little give. It does OK for an outdoors knife like on a Scandivex grind, but didn't have enough give for a kitchen knife. F3 Felt from Amazon has a nice give to give a great convexing for the kitchen knife. I flat grind on a glass platen first up to 120 grit. Then I switch to the F3 felt and work up from 60 or 80 all the way up to 220 or 320. Then I go to a leather platen and work up 120, 220, 320 and focus on the plunge cuts on the leather platen on up until I stop at the finest belt I want, usually a blue or grey ScotchBrite, or a cork belt loaded with compound. The leather platen helps give good plunge cuts and not wash them out and helps keep the grind line crisper. I use a plunge cut guide when grinding the blade until it is fully done to keep the grinds nice since a soft platen will mess with the plunge cuts. I usually do a convex on a full grind blade, not saber, but I have found with going to a S2-32 felt and then leather, I can keep a decently good grind line, but it does take a deft touch and practice. You need to let the belt do the work and not push too hard into the belt to keep a nice grind line. I can do several blades on one piece of leather or felt on my platen, when it gets worn, I use double sided tape to flip it over to the other side and when that wears, put a new piece on. I bought a square foot of Felt in both hardness last year and still have over half of each piece left. Most of my blades are satin finish anyway with scotchbrite belts or cork belts, which will slightly wash out grind lines.

The felt platen does a full convex, meaning it will convex towards the spine as well. You need a VFD to slow things down so you don't burn the steel, especially at higher grits. I have gone up to the SunMax M5 belts on the leather and felt platens, just use slow speed. Norax also work great on the felt and leather platen. It takes a while to build up a feel for the blade and how much to push into the felt to get a good convex, but not go too far with it. I also had good luck running the grinder in reverse and grinding edge up, but you need a face shield with the fine metal dust. You can really vary the grind and how thin it is behind the edge this way, but you need to slow the grinder way down.

Brian Housewertz (sp??) uses scotchbrite between leather and the metal platen, which lets it have some give, but the leather keeps the grind lines crisper. I have some F5 felt that is very soft, I may try leather over that to see how it does. Big point is to flat grind it first for the bulk removal and then switch to the felt. Felt will round out the edges, especially in the area of plunge cuts, hence the leather. I like the idea of the steel spring shim that will flex a touch; that is something to consider as well!

I go glass, hit the plunges, then go to leather, clean up the plunges more, then swap between felt and leather as I work up the grits if the blade has plunge cuts (most of my kitchen knives do not have plunge cuts), which is why I made a magnetic platen backer to make it easier to swap platens back and forth.

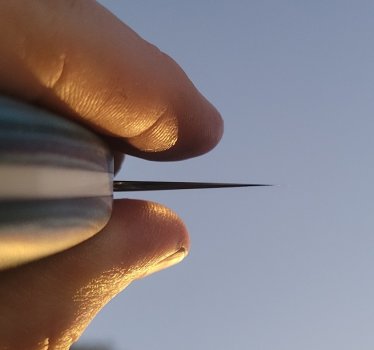

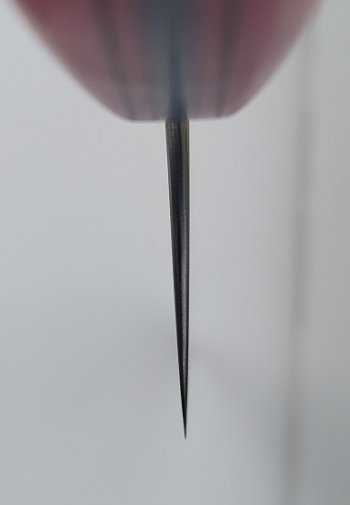

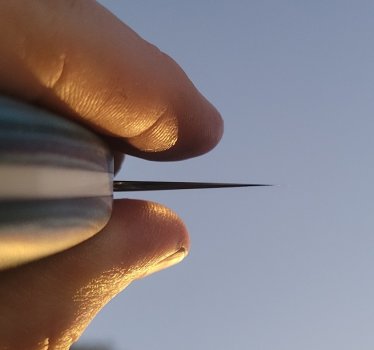

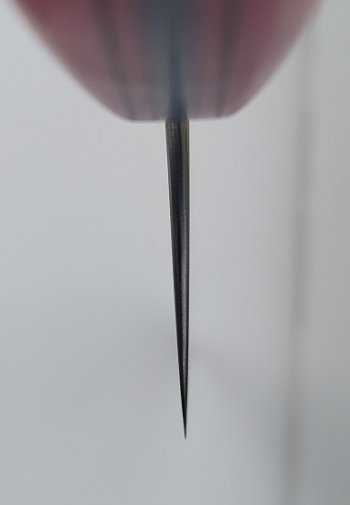

Some of my convex kitchen knives with felt platens:

Felt isn't a perfect system, but it does give excellent results once you learn how to use it!

Boss, any chance of a 2 wheel rotary platen setup with around 4" of slack between the rollers and adjustable tension to get a good amount of tension?

S2-32 Felt from McMaster-Carr has very little give. It does OK for an outdoors knife like on a Scandivex grind, but didn't have enough give for a kitchen knife. F3 Felt from Amazon has a nice give to give a great convexing for the kitchen knife. I flat grind on a glass platen first up to 120 grit. Then I switch to the F3 felt and work up from 60 or 80 all the way up to 220 or 320. Then I go to a leather platen and work up 120, 220, 320 and focus on the plunge cuts on the leather platen on up until I stop at the finest belt I want, usually a blue or grey ScotchBrite, or a cork belt loaded with compound. The leather platen helps give good plunge cuts and not wash them out and helps keep the grind line crisper. I use a plunge cut guide when grinding the blade until it is fully done to keep the grinds nice since a soft platen will mess with the plunge cuts. I usually do a convex on a full grind blade, not saber, but I have found with going to a S2-32 felt and then leather, I can keep a decently good grind line, but it does take a deft touch and practice. You need to let the belt do the work and not push too hard into the belt to keep a nice grind line. I can do several blades on one piece of leather or felt on my platen, when it gets worn, I use double sided tape to flip it over to the other side and when that wears, put a new piece on. I bought a square foot of Felt in both hardness last year and still have over half of each piece left. Most of my blades are satin finish anyway with scotchbrite belts or cork belts, which will slightly wash out grind lines.

The felt platen does a full convex, meaning it will convex towards the spine as well. You need a VFD to slow things down so you don't burn the steel, especially at higher grits. I have gone up to the SunMax M5 belts on the leather and felt platens, just use slow speed. Norax also work great on the felt and leather platen. It takes a while to build up a feel for the blade and how much to push into the felt to get a good convex, but not go too far with it. I also had good luck running the grinder in reverse and grinding edge up, but you need a face shield with the fine metal dust. You can really vary the grind and how thin it is behind the edge this way, but you need to slow the grinder way down.

Brian Housewertz (sp??) uses scotchbrite between leather and the metal platen, which lets it have some give, but the leather keeps the grind lines crisper. I have some F5 felt that is very soft, I may try leather over that to see how it does. Big point is to flat grind it first for the bulk removal and then switch to the felt. Felt will round out the edges, especially in the area of plunge cuts, hence the leather. I like the idea of the steel spring shim that will flex a touch; that is something to consider as well!

I go glass, hit the plunges, then go to leather, clean up the plunges more, then swap between felt and leather as I work up the grits if the blade has plunge cuts (most of my kitchen knives do not have plunge cuts), which is why I made a magnetic platen backer to make it easier to swap platens back and forth.

Some of my convex kitchen knives with felt platens:

Felt isn't a perfect system, but it does give excellent results once you learn how to use it!

Boss, any chance of a 2 wheel rotary platen setup with around 4" of slack between the rollers and adjustable tension to get a good amount of tension?

CDHumiston

KNIFE MAKER

I used to have a rotary platen and want to get one again, but they are expensive. Maybe next year. When I had the KMG rotary platen, I only really used one of the areas (the 2nd shortest gap area) and had to be careful of the belt cupping when grinding and putting a nasty 2" groove in the blade. With a tall kitchen knife, I had to be careful not to have the spine on the roller itself, so a 3-4" wide area between the rollers would be nice IMHO. Maybe BossDog can put together a kit that we can assemble with a ~4" gap between 2 rollers? Having 4 rollers is $200 alone in just rollers, so a 2 roller rotary platen may be more cost effective?

S2-32 Felt from McMaster-Carr has very little give. It does OK for an outdoors knife like on a Scandivex grind, but didn't have enough give for a kitchen knife. F3 Felt from Amazon has a nice give to give a great convexing for the kitchen knife. I flat grind on a glass platen first up to 120 grit. Then I switch to the F3 felt and work up from 60 or 80 all the way up to 220 or 320. Then I go to a leather platen and work up 120, 220, 320 and focus on the plunge cuts on the leather platen on up until I stop at the finest belt I want, usually a blue or grey ScotchBrite, or a cork belt loaded with compound. The leather platen helps give good plunge cuts and not wash them out and helps keep the grind line crisper. I use a plunge cut guide when grinding the blade until it is fully done to keep the grinds nice since a soft platen will mess with the plunge cuts. I usually do a convex on a full grind blade, not saber, but I have found with going to a S2-32 felt and then leather, I can keep a decently good grind line, but it does take a deft touch and practice. You need to let the belt do the work and not push too hard into the belt to keep a nice grind line. I can do several blades on one piece of leather or felt on my platen, when it gets worn, I use double sided tape to flip it over to the other side and when that wears, put a new piece on. I bought a square foot of Felt in both hardness last year and still have over half of each piece left. Most of my blades are satin finish anyway with scotchbrite belts or cork belts, which will slightly wash out grind lines.

The felt platen does a full convex, meaning it will convex towards the spine as well. You need a VFD to slow things down so you don't burn the steel, especially at higher grits. I have gone up to the SunMax M5 belts on the leather and felt platens, just use slow speed. Norax also work great on the felt and leather platen. It takes a while to build up a feel for the blade and how much to push into the felt to get a good convex, but not go too far with it. I also had good luck running the grinder in reverse and grinding edge up, but you need a face shield with the fine metal dust. You can really vary the grind and how thin it is behind the edge this way, but you need to slow the grinder way down.

Brian Housewertz (sp??) uses scotchbrite between leather and the metal platen, which lets it have some give, but the leather keeps the grind lines crisper. I have some F5 felt that is very soft, I may try leather over that to see how it does. Big point is to flat grind it first for the bulk removal and then switch to the felt. Felt will round out the edges, especially in the area of plunge cuts, hence the leather. I like the idea of the steel spring shim that will flex a touch; that is something to consider as well!

I go glass, hit the plunges, then go to leather, clean up the plunges more, then swap between felt and leather as I work up the grits if the blade has plunge cuts (most of my kitchen knives do not have plunge cuts), which is why I made a magnetic platen backer to make it easier to swap platens back and forth.

Some of my convex kitchen knives with felt platens:

View attachment 80971

View attachment 80972

View attachment 80973

View attachment 80974

Felt isn't a perfect system, but it does give excellent results once you learn how to use it!

Boss, any chance of a 2 wheel rotary platen setup with around 4" of slack between the rollers and adjustable tension to get a good amount of tension?

Love that grind! I've been doing a lot of kitchen knives lately. I'd love to see your leather and felt platen set up.

CDHumiston

KNIFE MAKER

Nice setup! I love the magnetic quick-change idea.

MTBob

Well-Known Member

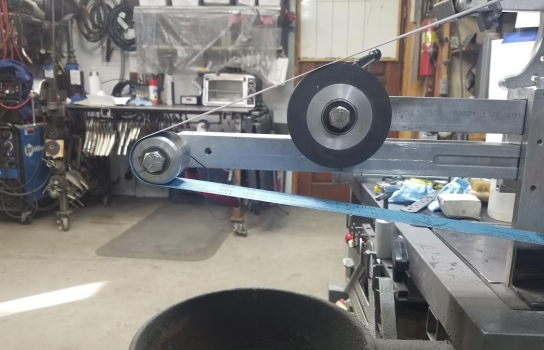

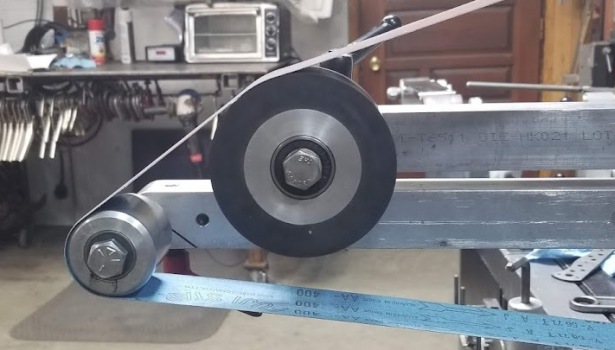

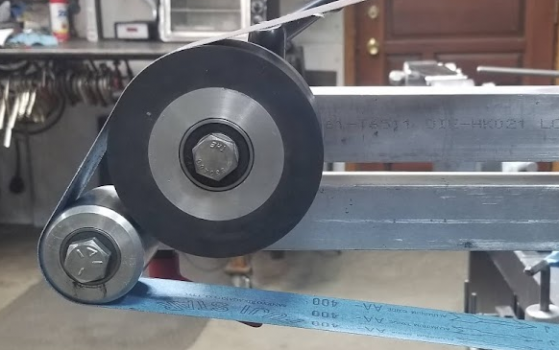

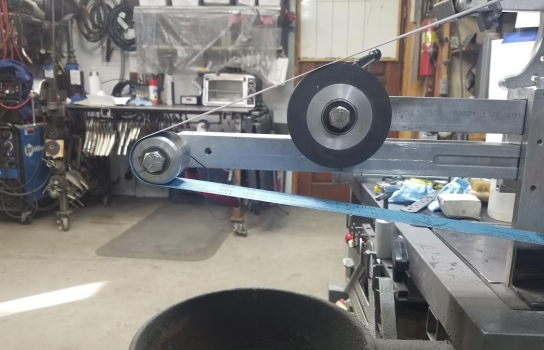

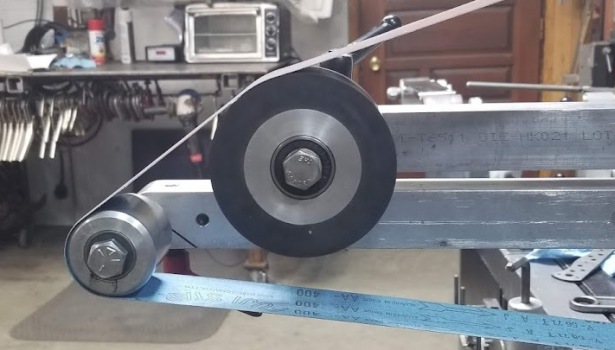

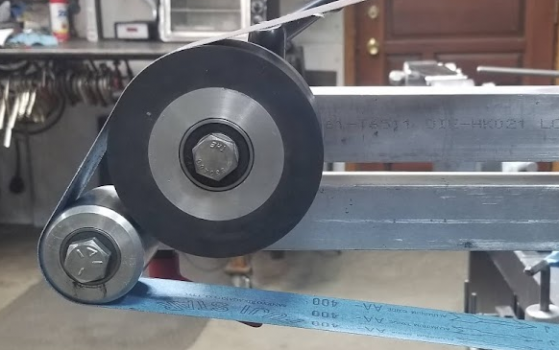

Here's a method of achieving a variable tensioned belt. This arrangement allows for more tension variations than fixed belt tension that rotary platens offer. Selecting different wheel sizes will offer even more belt tension alternatives. After using this arrangement I've not found a need for a rotary platen.

MTBob

Well-Known Member

I have several platen attachments that use various backing materials. The only reason I'm showing this is to note the added clip on the top of the metal backing that assures that the attachment won't slip or fall off the main platen. I use neodymium magnets to hold the attachment.

Also note that on this Reeder grinder that the platen can be quickly repositioned to accommodate the added thickness of the soft platen attachment - in this case, aligning the outer face of the platen attachment in line with the upper and lower wheels.

Also note that on this Reeder grinder that the platen can be quickly repositioned to accommodate the added thickness of the soft platen attachment - in this case, aligning the outer face of the platen attachment in line with the upper and lower wheels.

MTBob

Well-Known Member

Great idea, I'm going to do that too. Thanks!I put star knobs on my AmeriBrade platen so I don't need the allen wrench