Merle

Well-Known Member

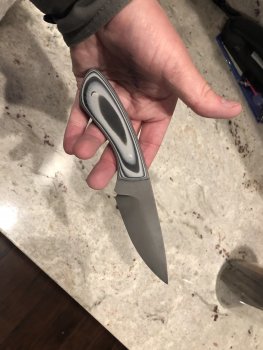

Well since I blew up my mini-cleaver in the quench this morning, I figured I’d try to finish the other knife I had in work. (This is the project that prompted my other post about finishing G-10.)

OAL is about 8” with a 3.75” edge length. No attempt at a hamon on this one but I etched in FeCl to get the patina look. The blade pattern is just one I found on a Google image search for knife templates.

The handles are gray/black Ultrex G-10, sanded to 220, no finish applied. I’m happy with the Ultrex G-10 look and am surprised how smooth and slick that material gets with just 220. I was planning to go to 600 or 800 but it doesn’t seem necessary.

It’s definitely not perfect, you can see how I ovaled the rear pin hole due to misalignment. And there’s plenty if other less visible flaws but overall I’m happy with how it turned out.

Thanks for looking.

Andy

OAL is about 8” with a 3.75” edge length. No attempt at a hamon on this one but I etched in FeCl to get the patina look. The blade pattern is just one I found on a Google image search for knife templates.

The handles are gray/black Ultrex G-10, sanded to 220, no finish applied. I’m happy with the Ultrex G-10 look and am surprised how smooth and slick that material gets with just 220. I was planning to go to 600 or 800 but it doesn’t seem necessary.

It’s definitely not perfect, you can see how I ovaled the rear pin hole due to misalignment. And there’s plenty if other less visible flaws but overall I’m happy with how it turned out.

Thanks for looking.

Andy