Chris Railey

Well-Known Member

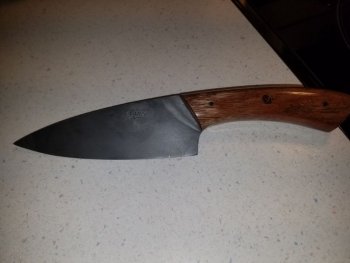

I think I am going to make a couple of chef's knives maybe in 8-10 inch range. I have been wanting to do so for a while now but I am wondering what thickness I should start with for a nice middle of the road blade which will slice well but also do some light chopping. The knife will be mainly for prep work, slicing boneless raw meat and vegetables. I have not made many kitchen blades so I would appreciate any advice an experienced kitchen knife person could give. The knife will be high carbon steel more than likely 1080 or 1084 if I can find it thinner than 1/8. Thanks in advance...Chris