I did a search for previous results for book recommendations but didn't get any results. So, can you folks offer any suggestions for me.

I'm kinda looking for beginner books covering the steps in order for basic knives. Also covering normalizing and other heat treating processes.

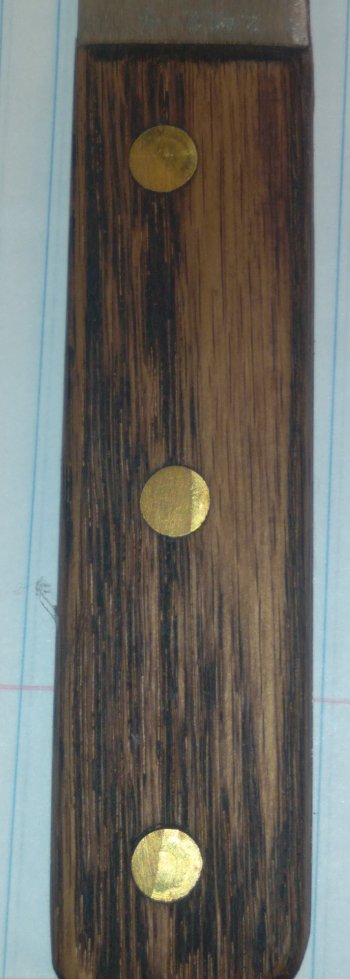

I've made four skinning knives but sorta fumbled thru it. None of my rivets came out straight or even. I used split chain saw bars for the blades and would like to start using 1080 or 1084 steel. ( I think )

Thanks in advance. Tony

I'm kinda looking for beginner books covering the steps in order for basic knives. Also covering normalizing and other heat treating processes.

I've made four skinning knives but sorta fumbled thru it. None of my rivets came out straight or even. I used split chain saw bars for the blades and would like to start using 1080 or 1084 steel. ( I think )

Thanks in advance. Tony