We have a knife in the kitchen my wife loves and a friend of ours saw it and commented she would like one similar to it. Her and her husband have become friends of ours and a great support for us out here so I'd like to make it for them for nothing. But I've been kind of stuck on a design and was wondering if I could get some ideas.

The picture of the original knife is in "Blizzard day" thread.

I think what attracts people to it is the short comfortable handle and the angle of the edge in relation to the handle. It seems to lend itself to a push cut with very little resistance.

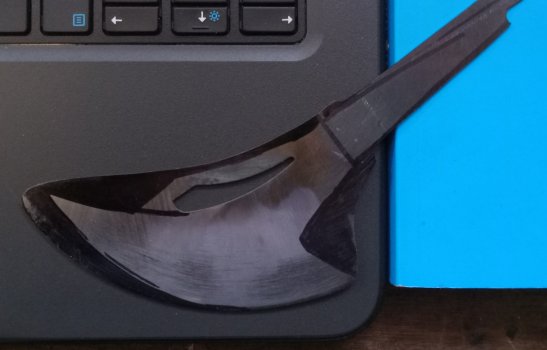

Here's a shot of what I'm thinking so far. To me it doesn't seem to lend itself to the same ease of cutting as the other. But I really don't like the hook on the heel of the blade on the first. Some of the "quarter" knives I looked up have that hook, too. But in my drawing you'd lose cutting some edge, which is actually nice on a push knife for longer cuts. To fix that I tried to add to the tip what I took off the heel.

I just don't think it's got a good feel, just by looking at it.

I've also only got 2" width that I can fit into the forge so not sure how to implement a tang sticking out away from the edge at that angle.

The picture of the original knife is in "Blizzard day" thread.

I think what attracts people to it is the short comfortable handle and the angle of the edge in relation to the handle. It seems to lend itself to a push cut with very little resistance.

Here's a shot of what I'm thinking so far. To me it doesn't seem to lend itself to the same ease of cutting as the other. But I really don't like the hook on the heel of the blade on the first. Some of the "quarter" knives I looked up have that hook, too. But in my drawing you'd lose cutting some edge, which is actually nice on a push knife for longer cuts. To fix that I tried to add to the tip what I took off the heel.

I just don't think it's got a good feel, just by looking at it.

I've also only got 2" width that I can fit into the forge so not sure how to implement a tang sticking out away from the edge at that angle.