Jon Buescher

Well-Known Member

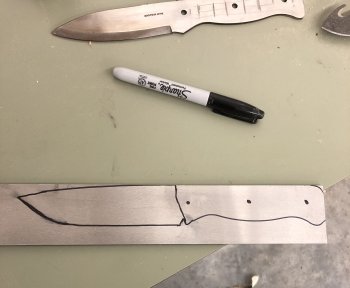

This thread is to catalog my adventure in knife making and my work in progress

Mine is like that as well but being carefull of where I put the various pieces of equipment has meant a reasonaby coherent layout.The shop is going to be multi use so I may not have the perfect production set up but it will have to work for me

Tell me more about this!Aaaand now I know what the temp will be in my forge! No more scorched metal