Welcome Robert and good for you!! Not only in learning something new but in your quest for the monies to go to the cancer trust. Anyone who's life has never been touched by cancer won't understand!!

All the info on tempering is good, but be darn sure the oven is actually at 400F range. Oven and toaster oven thermostats are usually not that accurate. Get an actual thermometer that can read to 500F (or appropriate C) to check actual temps.

Ken is 100% correct on the oven and temps.

Re harden, again reach red until it will not stick to magnet, plunge into newish engine oil or water, stir for 15 seconds and let air cool until I can pick it up bare handed, I run a file over blade and it is rock hard

The best quench oil would be something like Parks 50. Check the link on the right hand side of the forum.

Parks AAA quench oil MSDS Parks AAA quench oil tech data

If you are unable to get that kind of quench oil, because availability or cost

(and believe me I understand the cost issue). For your quench try Peanut or Canola oil, I think they may give better results!!

By

stir for 15 seconds do you mean, (stir like you would your tea)?

Couple more things on the checklist are dipping straight in the quench and using either a dunking (like jigging a lure) motion or slicing like you're cutting the oil. Vertical quench works very well for me. When you stir one side of the blade will not be cooled as fast or equally to the other side. Grant you it may seem like something minute but the steel doesn't think so! By stirring you are not equalizing the heat reduction to both sides of the blade during the quench.

Done the hand sanding, wet and dry, polished with mop and 3 compounds, successfully hardened it so magnet did not stick, as I tried to straighten it prior to tempering it cracked in 2 , I said a naughty word.

Knife making will sometimes make you say a naughty word!!

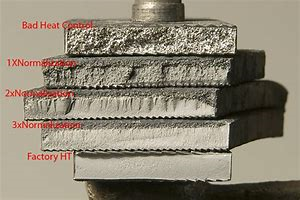

When you broke the two did you look at the grain of the steel at the break?

If the grain looks like this,

It is too large. The grain in this picture is too large as well but only on one side of the knife!

The advice given from this pic by a seasoned maker, ( Robert Dark ) was as follows. Either you lost control of your heat and over heated the blade prior to quench, OR, you didn't do any normalizing cycles prior to quench.

The maker of this knife said, this was an attempt at a hamon and the part of the blade that has the largest grain was the part that was covered with clay, isn't this the purpose of the clay.

The clay is suppose to slow the hardening in the area it covers so that it does not get as hard but, should not grow the grain but very little. So more than likely it was a failure of the quench process!!! Or he did get the blade too hot before the quench!!

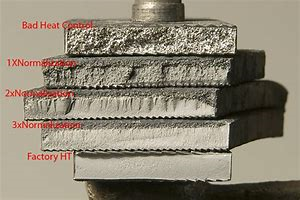

Now here is a stack photo that shows it all!!

Notice the one on the bottom, that is about as perfect of a grain you could ask for. I keep these photos for reference purposes and dig then out every so often as a visual to what I am trying to say. Sometimes my thoughts don't come out so well in words!!

Two things that I have learned about knife making is. Number one, consistency is the name of the game and a moment of wrong in the entire process can and will make for some bad results.

Good luck to you Robert and don't forget to come back. Oh and the number two thing I have learned about knife making is. The only dumb question, is the one you did not ask!!