KentuckyFisherman

Well-Known Member

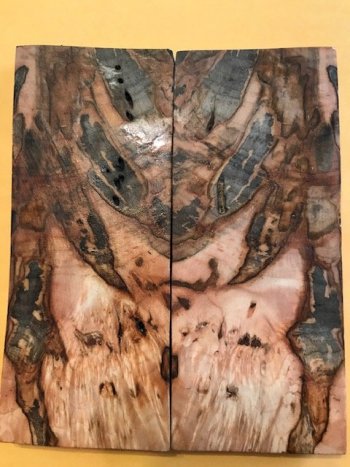

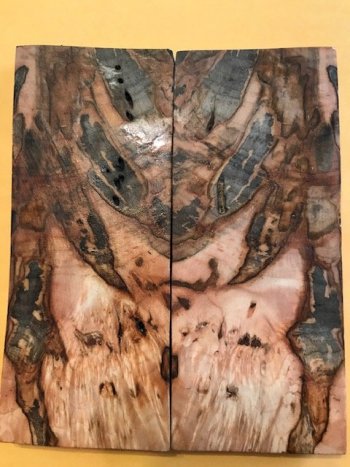

I sent several pair of scales for stabilizing and got them back a few days ago. One set came back with one of the scales seriously warped. In all fairness to the company, which won't be named, the scales weren't perfectly flat when I sent them, but I wouldn't have sent this pair if they were this far out of flat. The processor did have to dry the wood a bit more, so that may have been when any existing warp was made worse.

Regardless, I need advice about how to recover what I can from the badly warped scale. Do I sand the convex side, the concave side, or a little of both? To get a flatter scale, it's going to end up thinner regardless, correct? While this set started out as a nicely bookmatched pair, I'm not hung up on that and worse case is that I just match up the one flat scale here with another piece that's close in appearance and abandon the warped scale.

What's your suggestion?

Regardless, I need advice about how to recover what I can from the badly warped scale. Do I sand the convex side, the concave side, or a little of both? To get a flatter scale, it's going to end up thinner regardless, correct? While this set started out as a nicely bookmatched pair, I'm not hung up on that and worse case is that I just match up the one flat scale here with another piece that's close in appearance and abandon the warped scale.

What's your suggestion?

Last edited: