Merle

Well-Known Member

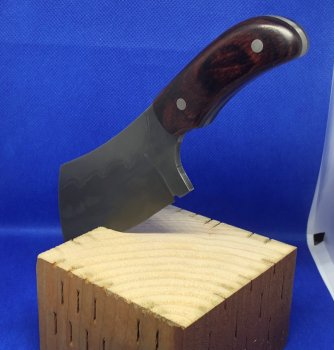

This was my attempt at re-making the mini-cleaver that I cracked badly during quench a few months ago. Same material and HT process as before, but I left the beveled edge much thicker this time. And it worked, no cracks!

I tried for a hamon again, and got some definite activity, but just wasn't able to etch and polish it into a nice distinct "Doyle-esque" line.

This was also my first blade that I put a makers mark on; I got a hot stamp from Buckeye but need to practice more with it. The impression wasn't deep enough to withstand all the subsequent sanding and you can see it's starting to disappear. Next time I will really whack it good while it's still orange.

The blade is 5/32" thick 1075 with Dymalux "rosewood" scales and 3/16" dia mild steel pins. The Dymalux really sanded up nice and I put a few coats of Tru Oil on it.

Photos were taken using my new $13 light tent and I used Dennis's tip on cropping the photos, which I think made a huge improvement to the photo quality.

thanks for looking.

andy

I tried for a hamon again, and got some definite activity, but just wasn't able to etch and polish it into a nice distinct "Doyle-esque" line.

This was also my first blade that I put a makers mark on; I got a hot stamp from Buckeye but need to practice more with it. The impression wasn't deep enough to withstand all the subsequent sanding and you can see it's starting to disappear. Next time I will really whack it good while it's still orange.

The blade is 5/32" thick 1075 with Dymalux "rosewood" scales and 3/16" dia mild steel pins. The Dymalux really sanded up nice and I put a few coats of Tru Oil on it.

Photos were taken using my new $13 light tent and I used Dennis's tip on cropping the photos, which I think made a huge improvement to the photo quality.

thanks for looking.

andy