Mark Barone

Well-Known Member

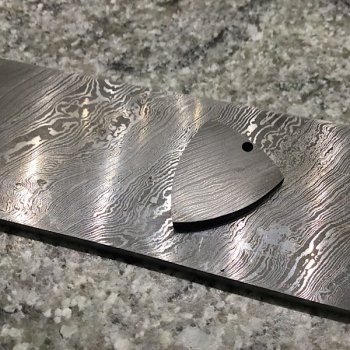

After sanding, what is the best way to bring Damascus back. I have some test pieces I want to try? I have ferric chloride, apple cider vinegar on hand. I tried soaking in straight FC but it seem to darken the whole piece. I left it in for about 3 -5 minutes. I can't seem to find find any videos on this.