Steven Janik

SUPERMOD & AWARDS BOSS

Scalloped Bolster Inlays part 1

This may be old hat for some but it is a great way to use a contrasting bolster that is thinner than your scale stock without just using a pile of spacers.

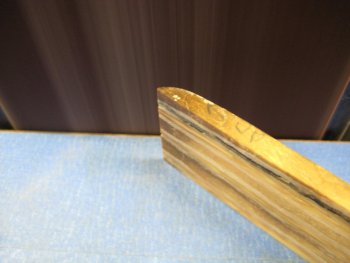

pic #1 shows the finished product.

pic #2 shows the two scales taped together. I put a 1/4" block between them on this set because the carbon is thin and it's just easier to hold on to.

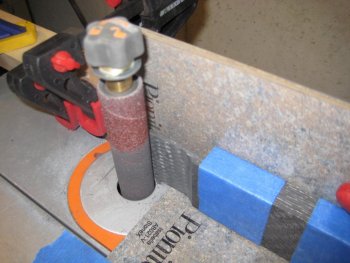

pic #3 shows the stock being plunged into the oscillating spindle sander. This can also be done with a drum sander in your drill press or on the 1" wheel of your grinder. I just like this little oscillator for this kind of task. You flip the piece over and do alternating ends and I add the laminate counter top sample as .040 spacers but you can also move your fence as you progress. You must be slow and careful because by pushing stock between a rotary tool and a fence you could create a jamb and a flying projectile.

This may be old hat for some but it is a great way to use a contrasting bolster that is thinner than your scale stock without just using a pile of spacers.

pic #1 shows the finished product.

pic #2 shows the two scales taped together. I put a 1/4" block between them on this set because the carbon is thin and it's just easier to hold on to.

pic #3 shows the stock being plunged into the oscillating spindle sander. This can also be done with a drum sander in your drill press or on the 1" wheel of your grinder. I just like this little oscillator for this kind of task. You flip the piece over and do alternating ends and I add the laminate counter top sample as .040 spacers but you can also move your fence as you progress. You must be slow and careful because by pushing stock between a rotary tool and a fence you could create a jamb and a flying projectile.

Last edited: