Steven Janik

SUPERMOD & AWARDS BOSS

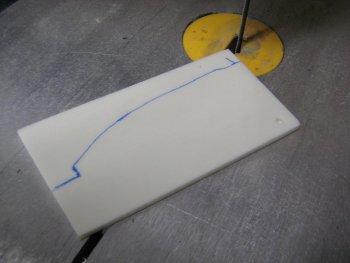

This is gonna fall into two categories so it may get switched to Custom Modification Forum.

I was recently given a "BULLSHARK" framelock folder kit by Jonathon of Custom Knife Kits so I thought I would see what could be done with it. There have been questions about kits before on this forum and by no means am I trying to push this over as a custom built knife, BUT if you are new to folders or just starting out and have limited equiptment and funds this is a great way to start . I used this one simply as a platform for this tutorial and will keep it in my pack or give it to charity or some kid. I'm open to suggestions but will not adopt any of you. (unless of course you have good gardening skills, a cnc mill, a great place to hunt or just a lot of disposable income and will buy shoes and purses for my wife.)

I was amazed at the quality of this kit for the money, under $30.00. I love liner locks and full scales so I did a full on conversion as follows.......

This is the kit as shipped with radiused edge frames and textured G10 half scales.

The detent ball is already in place when shipped.

This shows the radiused frame edges which I remove later on to accept full scales.

This is the blade as shipped with thumb stud attached and already pocket drilled for detent ball.

These are the half scales and clip as supplied. I did not use these.

I was recently given a "BULLSHARK" framelock folder kit by Jonathon of Custom Knife Kits so I thought I would see what could be done with it. There have been questions about kits before on this forum and by no means am I trying to push this over as a custom built knife, BUT if you are new to folders or just starting out and have limited equiptment and funds this is a great way to start . I used this one simply as a platform for this tutorial and will keep it in my pack or give it to charity or some kid. I'm open to suggestions but will not adopt any of you. (unless of course you have good gardening skills, a cnc mill, a great place to hunt or just a lot of disposable income and will buy shoes and purses for my wife.)

I was amazed at the quality of this kit for the money, under $30.00. I love liner locks and full scales so I did a full on conversion as follows.......

This is the kit as shipped with radiused edge frames and textured G10 half scales.

The detent ball is already in place when shipped.

This shows the radiused frame edges which I remove later on to accept full scales.

This is the blade as shipped with thumb stud attached and already pocket drilled for detent ball.

These are the half scales and clip as supplied. I did not use these.

Attachments

Last edited: