Ernie Swanson

SASSY PINK LUUNCHBOX KNIFE MAKER

I got an idea for a thread in the tutorial section!!

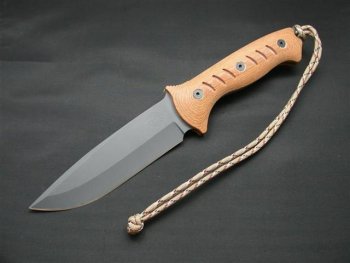

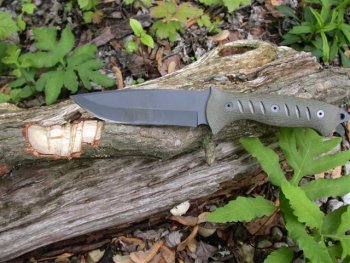

I was wondering if you all could send me pics and descriptions of any knife finishes you know of or do.

I am looking for anything from mirror, 400 grit, bead blasted, tumbled, blued, and even painted. Anything that can be done to a knife!!!!

I am trying to get a big list of the different finishes on blade with pictures and a description of each.

you can either pm me, post here or email me at bigern26@gmail.com

Thanks for any help

ErnDOG 2thumbs

I was wondering if you all could send me pics and descriptions of any knife finishes you know of or do.

I am looking for anything from mirror, 400 grit, bead blasted, tumbled, blued, and even painted. Anything that can be done to a knife!!!!

I am trying to get a big list of the different finishes on blade with pictures and a description of each.

you can either pm me, post here or email me at bigern26@gmail.com

Thanks for any help

ErnDOG 2thumbs