Calvin Robinson

Moderator Christian Forum

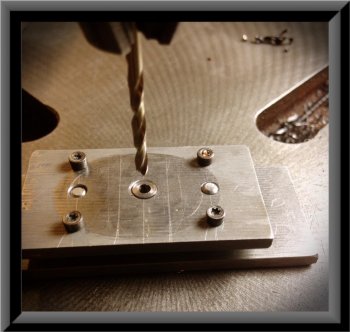

I use washers in the construction of my slipjoint knives to provide relief from getting radial scratches on the tang of the knife and to provide a metal bearing surface on my Linerless knives, I usualy make these out of stainless steel but today I made a batch out of bronze.

These washers are for use with a 3/32" pivot pin so I make them .096" ID X .285" OD X .008"

Yall follow along and please feel free to ask any questions,make comments,or offer any advice.

And please forgive the poor quality cell phone photos.

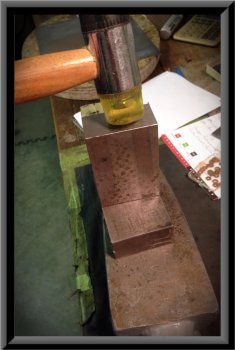

I begin by cutting 3/8" squares from .008" bronze shim stock.

These washers are for use with a 3/32" pivot pin so I make them .096" ID X .285" OD X .008"

Yall follow along and please feel free to ask any questions,make comments,or offer any advice.

And please forgive the poor quality cell phone photos.

I begin by cutting 3/8" squares from .008" bronze shim stock.