dswait

Well-Known Member

I have a neighbor who does a lot of fishing on his boat and really wanted a fillet knife. He insisted on stainless steel and a plastic handle to stand up against salt water. Since I don't have the means to heat treat stainless yet, I ordered a fillet knife blank from our good friends USA knife makers.

I already put the handle on the knife which is made from some kind of white polyethylene (kind of like a kitchen cutting board) given to me to use for a knife handle from a good friend. This material is really tough to work with, I went through at least 2 ceramic 60 grit belts trying to grind it down, that stuff does not move. After I finish polishing the blade, I will spray the handle with plasti dip. I've never used plasti dip before, so it will be interesting to see how this comes out.

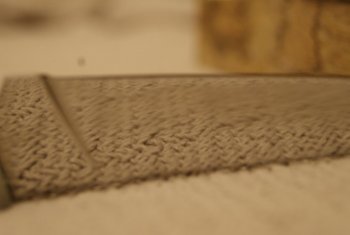

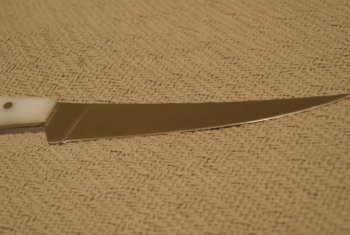

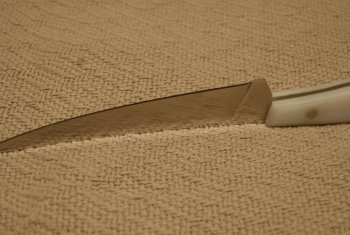

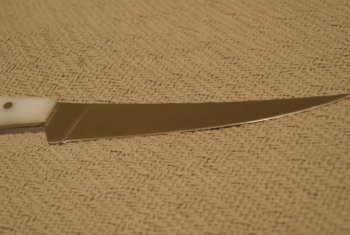

Here is a photo of the fillet knife with handle before polishing.

Some more pictures

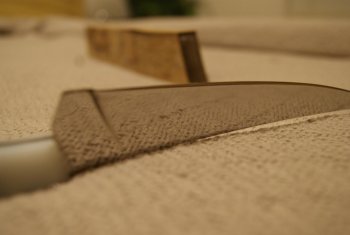

I did start polishing one side for about an hour before I had started taking pictures. The side on the left picture was the side I started working on.

To polish a blade on a grinder, it is important to use the following two safety items. The goggles will protect your eyes from any debris that comes out of the grinder and the hat will protect your head in case the belt snaps off the grinder. It hasn't happened to me yet, but I've heard stories so it's better to be safe than sorry.

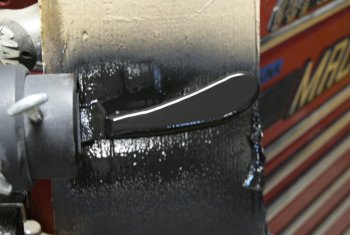

To polish the blade, I use a cork belt with a green chrome oxide polishing compound brick on a 1x30 belt grinder.

Since the blade has already been heat treated, allowing it to get hot while polishing on the grinder can undo the heat treatment. Therefore I use a pitcher filled with glass cleaner to keep my blade cool at all times. I usually use water, but when polishing I switch to glass cleaner. I like to think that it helps with the polishing, and I've found that helps against rust building up while working with the blade. While this fillet knife is stainless steel, I've had my first knife I was working on start building rust within an hour after I started grinding and dumping in water. Glass cleaner seems to help against that.

I already put the handle on the knife which is made from some kind of white polyethylene (kind of like a kitchen cutting board) given to me to use for a knife handle from a good friend. This material is really tough to work with, I went through at least 2 ceramic 60 grit belts trying to grind it down, that stuff does not move. After I finish polishing the blade, I will spray the handle with plasti dip. I've never used plasti dip before, so it will be interesting to see how this comes out.

Here is a photo of the fillet knife with handle before polishing.

Some more pictures

I did start polishing one side for about an hour before I had started taking pictures. The side on the left picture was the side I started working on.

To polish a blade on a grinder, it is important to use the following two safety items. The goggles will protect your eyes from any debris that comes out of the grinder and the hat will protect your head in case the belt snaps off the grinder. It hasn't happened to me yet, but I've heard stories so it's better to be safe than sorry.

To polish the blade, I use a cork belt with a green chrome oxide polishing compound brick on a 1x30 belt grinder.

Since the blade has already been heat treated, allowing it to get hot while polishing on the grinder can undo the heat treatment. Therefore I use a pitcher filled with glass cleaner to keep my blade cool at all times. I usually use water, but when polishing I switch to glass cleaner. I like to think that it helps with the polishing, and I've found that helps against rust building up while working with the blade. While this fillet knife is stainless steel, I've had my first knife I was working on start building rust within an hour after I started grinding and dumping in water. Glass cleaner seems to help against that.

Last edited: