Just had these ordered a couple weeks ago so I figured this would be a good time for a WIP!

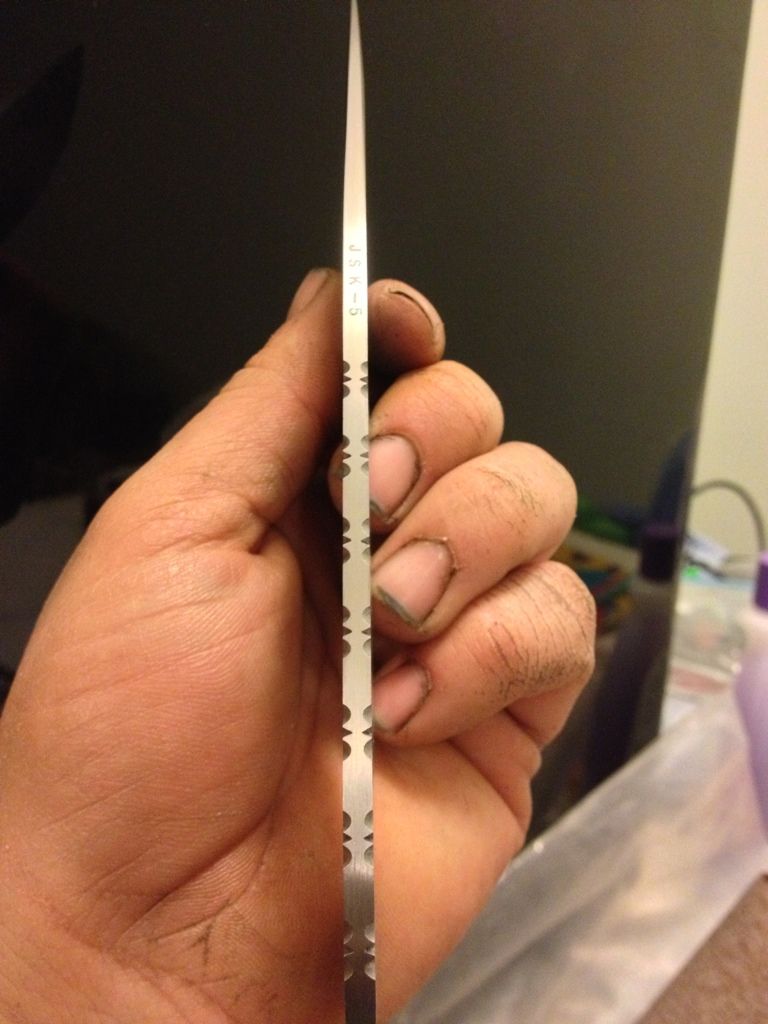

Stock removal from 1084. I have the blades cut out and rough ground. I am working on refining the lines with my files. This is the latest progress so far. More pictures to come!

Stock removal from 1084. I have the blades cut out and rough ground. I am working on refining the lines with my files. This is the latest progress so far. More pictures to come!