Brad Lilly

Moderator and Awards Boss

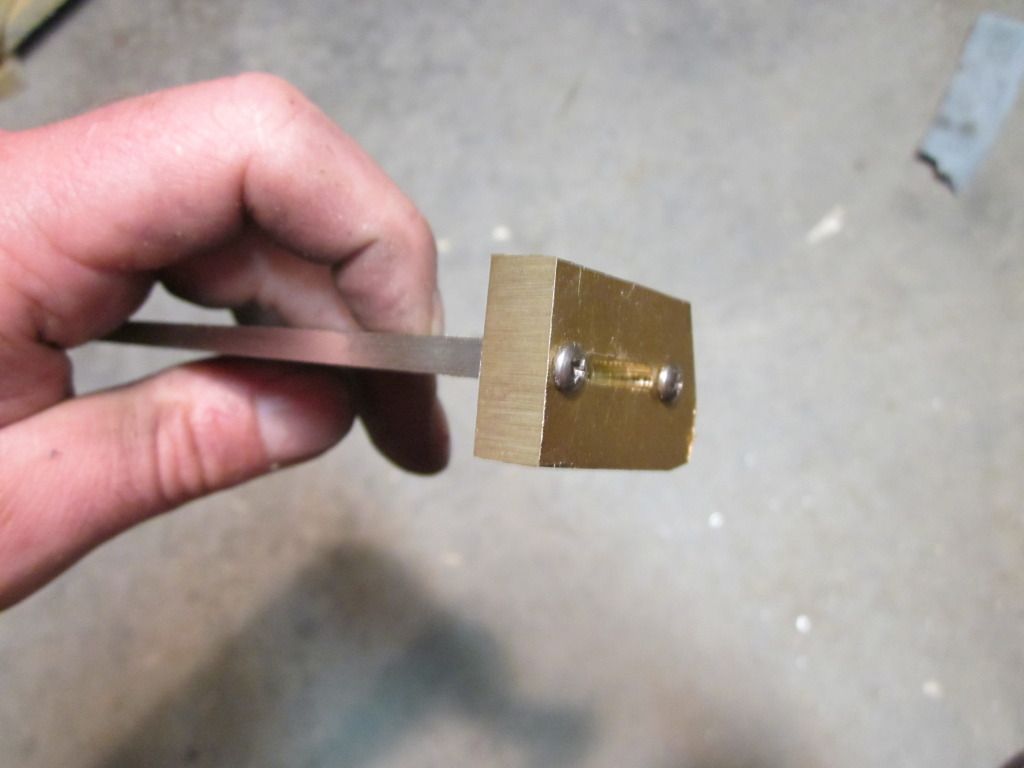

I’m going to do a WIP on a frame handle bowie. I plan on using mild steel for the frame and guard, a little brass and kirinite scales. My knife has distal taper in the blade and tang.

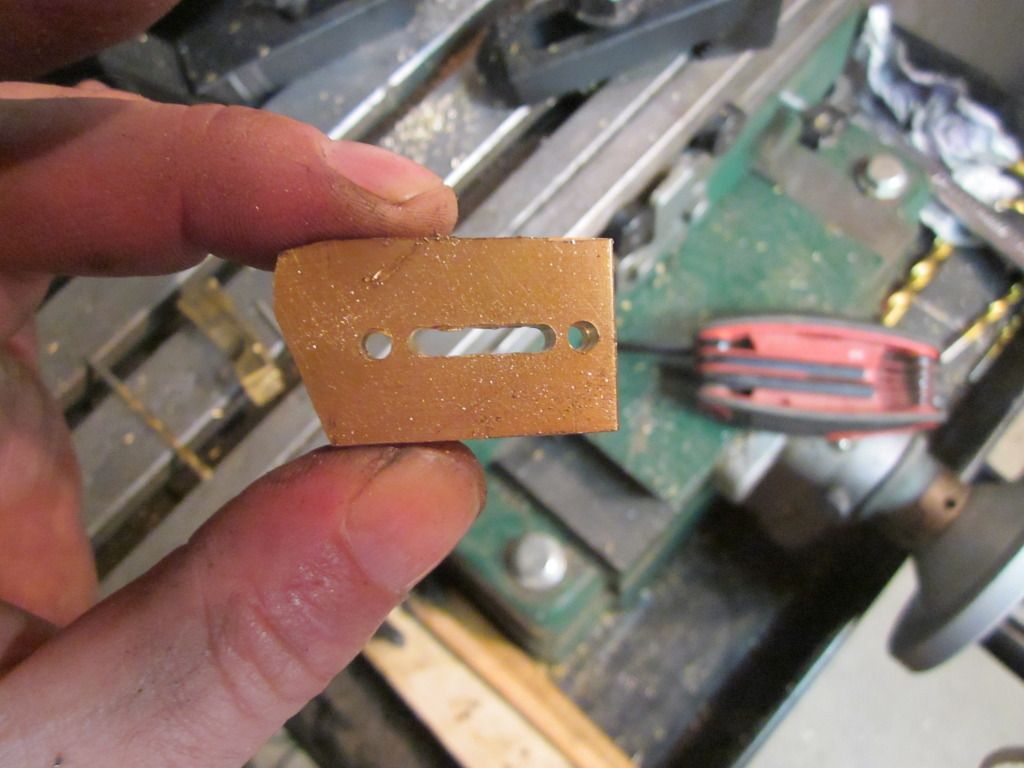

Here are the raw materials, I chose 3/16” mild steel for the guard and frame.

I like to use over sized steel to allow me more freedom in squaring the guard up.

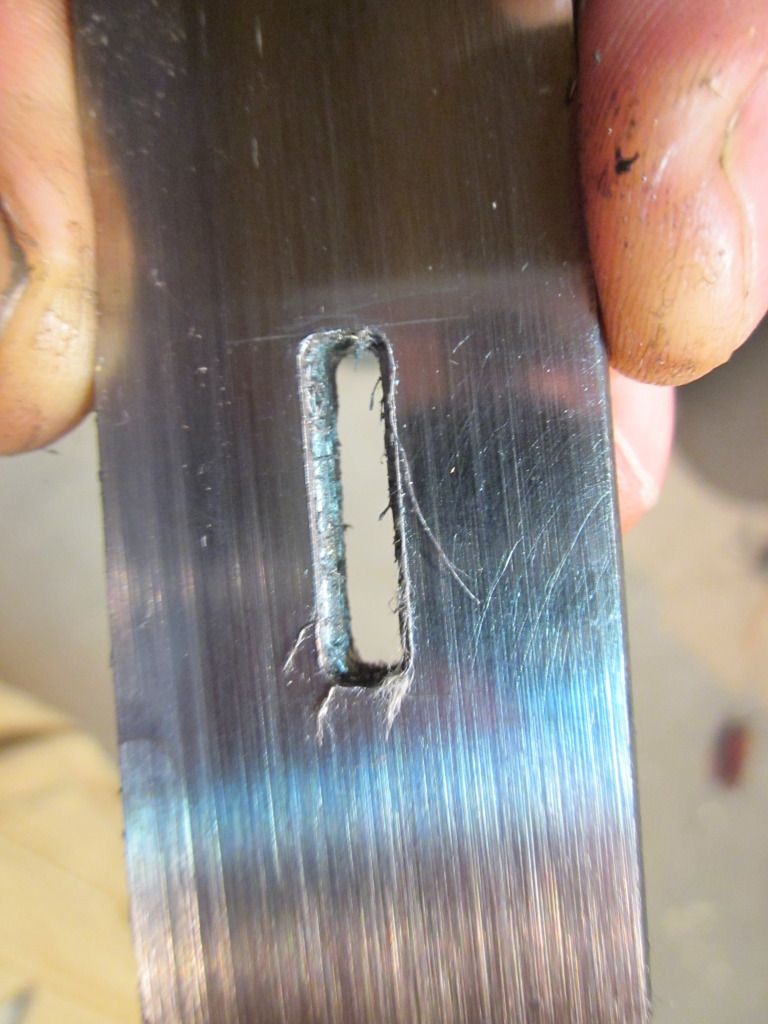

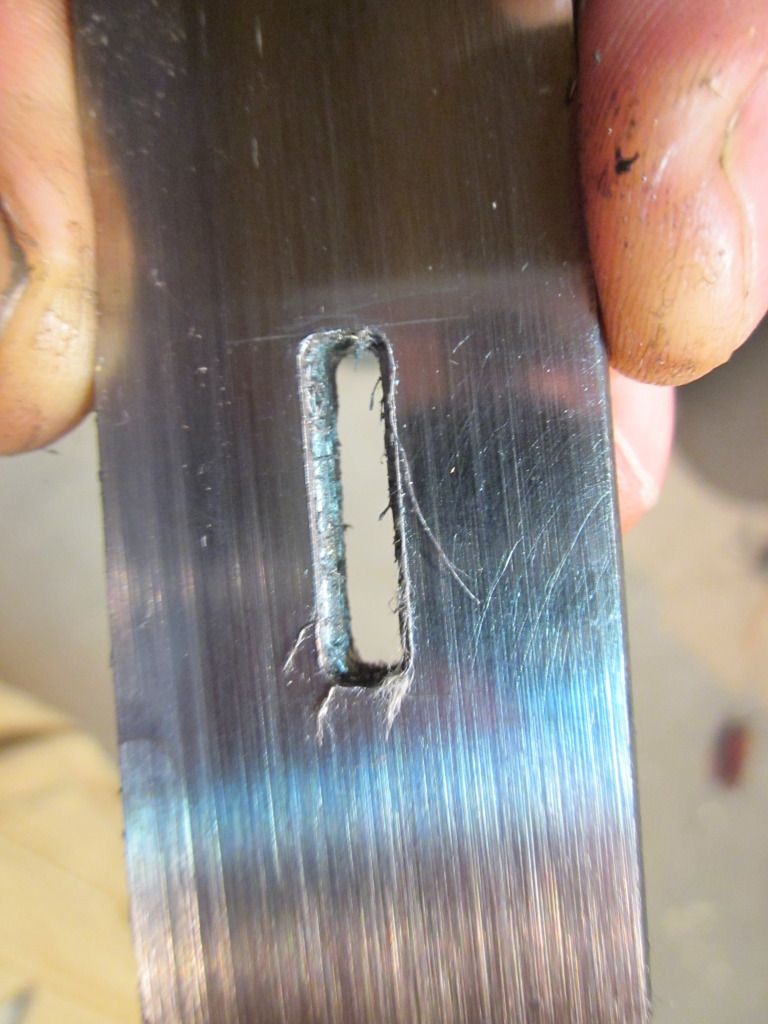

I mill the back of the guard, so the face of the guard is down on the table. The reason for this is I like to mill the slot wider on the handle side. When I’m filing the slot for the final fit I’m filing at and angle (Narrow at the front). This keeps me from filing away too much material where the guard and ricasso meet.

Here are the raw materials, I chose 3/16” mild steel for the guard and frame.

I like to use over sized steel to allow me more freedom in squaring the guard up.

I mill the back of the guard, so the face of the guard is down on the table. The reason for this is I like to mill the slot wider on the handle side. When I’m filing the slot for the final fit I’m filing at and angle (Narrow at the front). This keeps me from filing away too much material where the guard and ricasso meet.