Mark Behnke

Well-Known Member

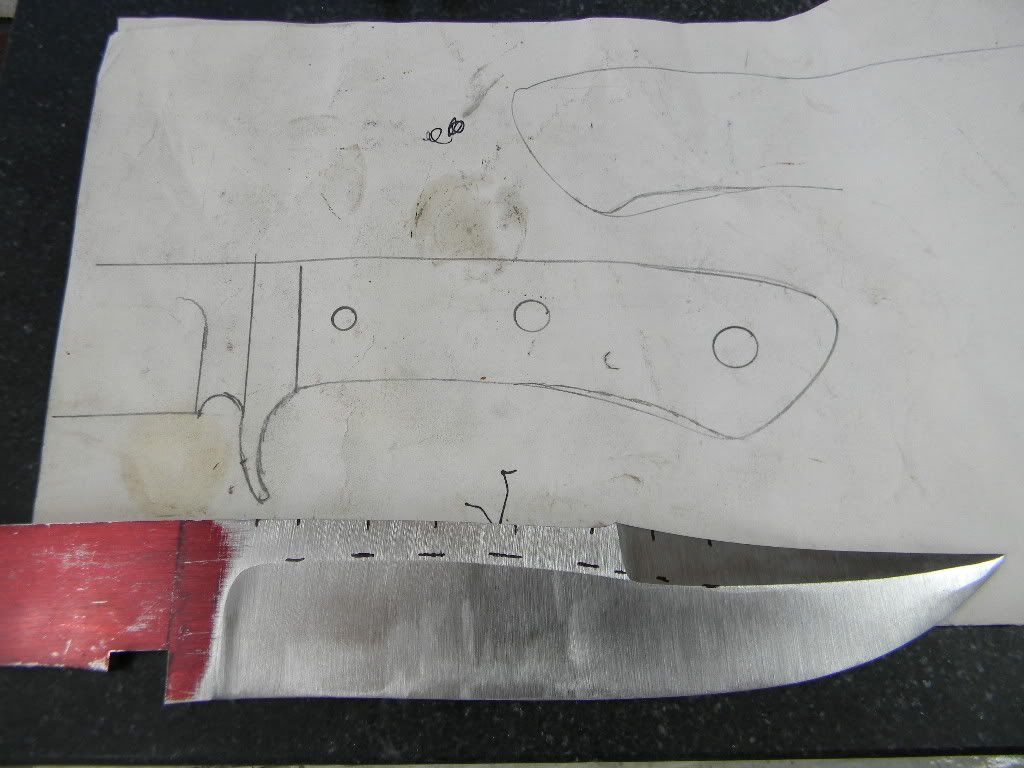

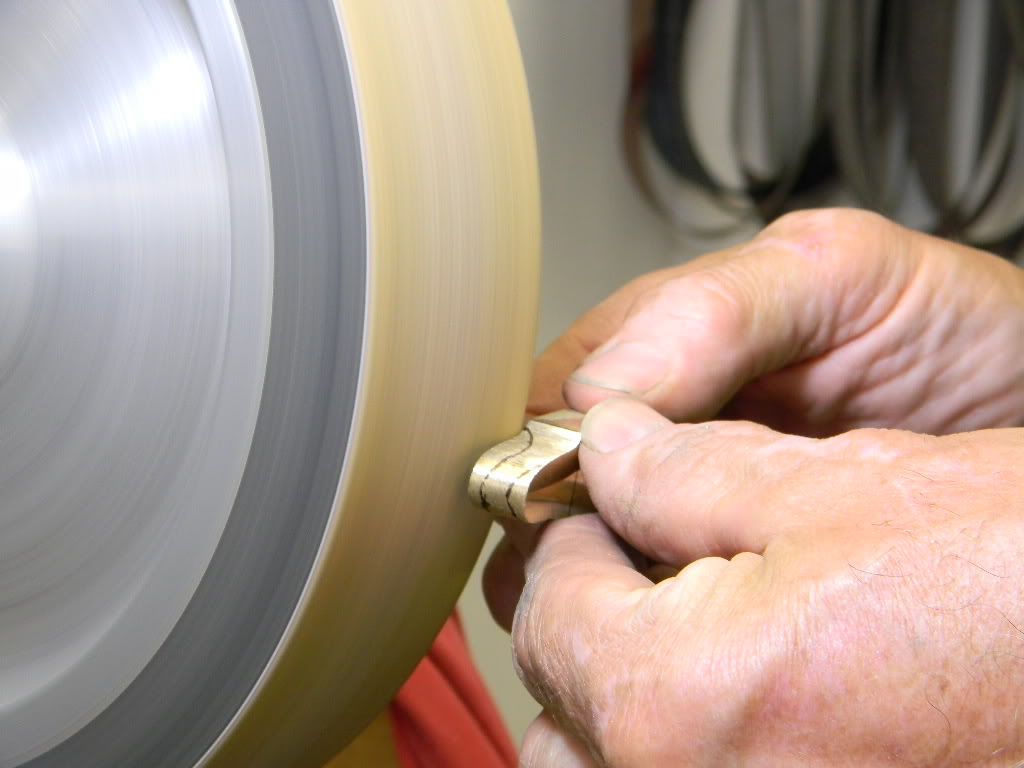

A few snap shots as I go along.

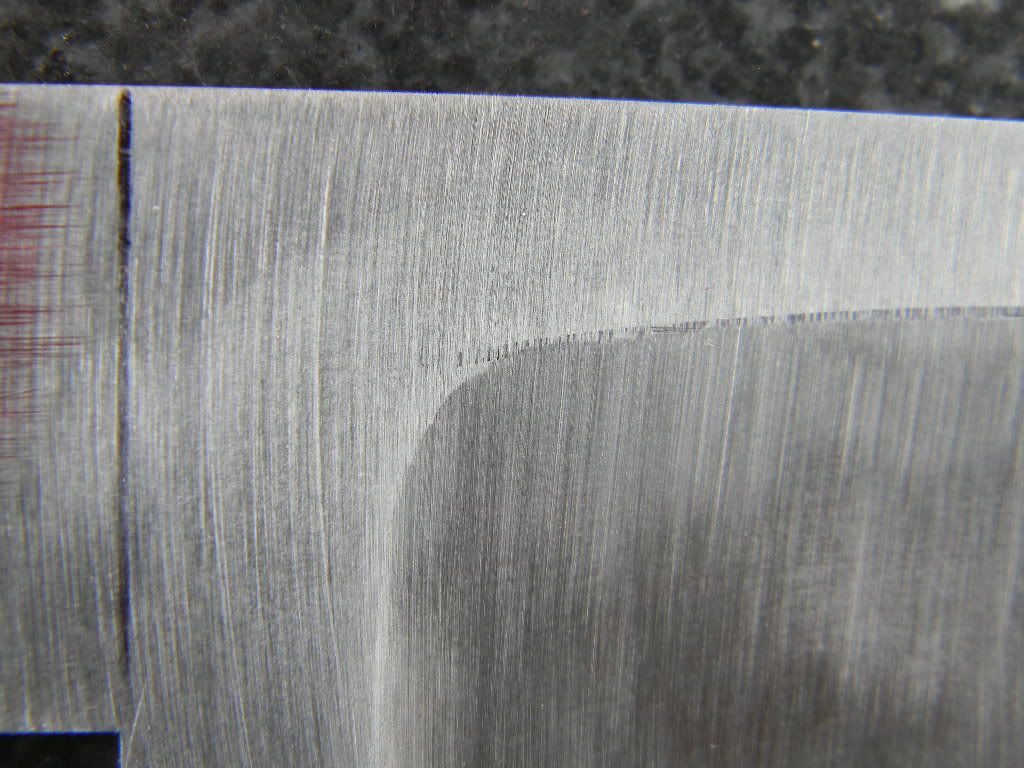

Ats-34 blade, tapered tang

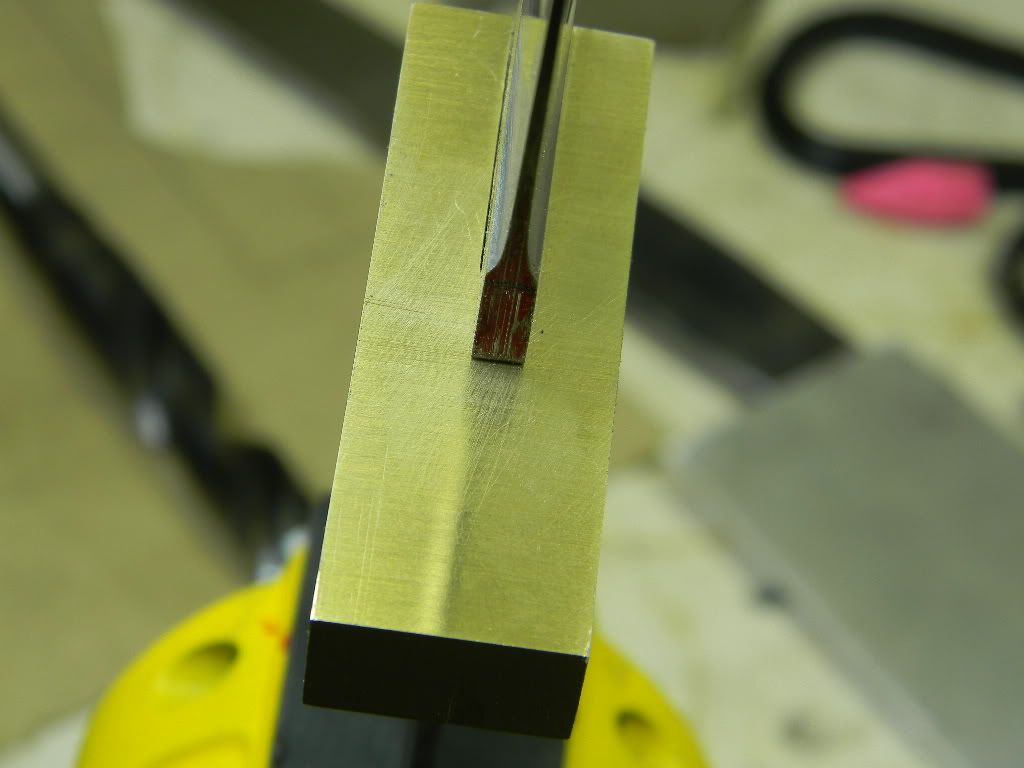

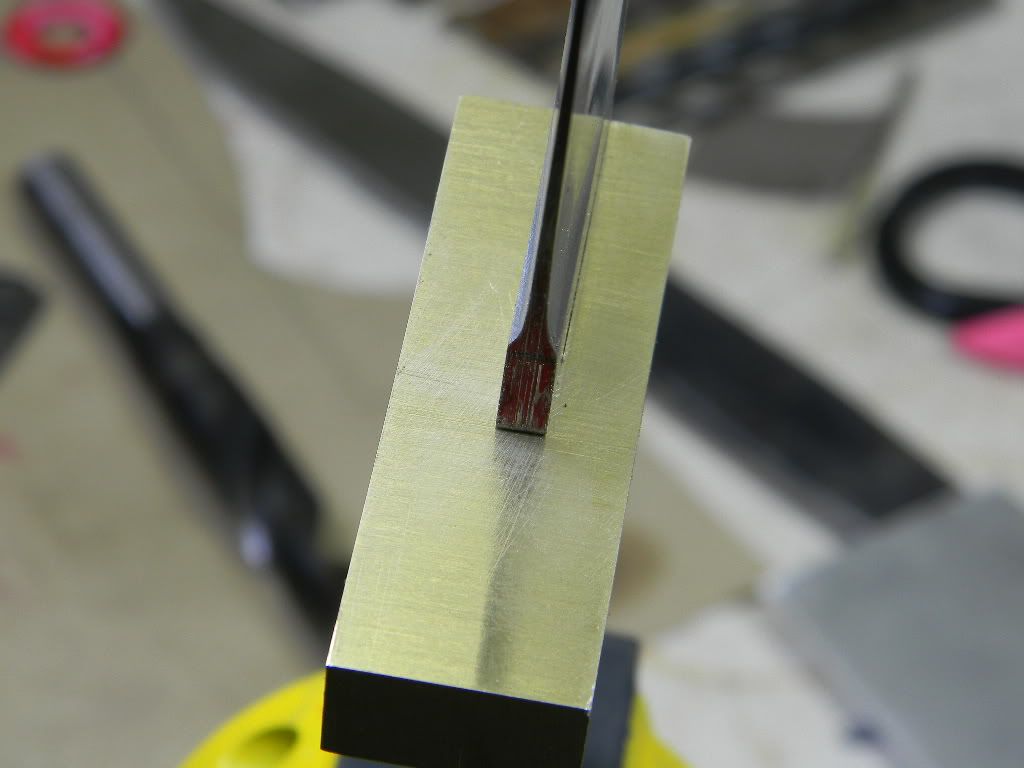

304 SS guard

I have an old round ram Bridgeport hooked to the KMG VFD so the guard blank was milled down from hot rolled 304 SS (read no flat or parallel surface) this is my first attempt at using a mill so an all day job and still not done.

Next, grind the bevels, taper, drill, heat treat, then finish the guard ,more mill time lots of bugs to work out on the mill.

Ats-34 blade, tapered tang

304 SS guard

I have an old round ram Bridgeport hooked to the KMG VFD so the guard blank was milled down from hot rolled 304 SS (read no flat or parallel surface) this is my first attempt at using a mill so an all day job and still not done.

Next, grind the bevels, taper, drill, heat treat, then finish the guard ,more mill time lots of bugs to work out on the mill.

Last edited by a moderator: