Josh Dabney

Moderator

Heya dogs,

Tax time has come again and although I'm wanting a new pistol in a bad way that hasn't over-ridden my endless need to feed the addiction :biggrin:

Tax time = TOOL time in the Dabney shop.

Rotary Platen has been ordered !:s11779:

Here's what I've got on my plate to build-

1 1/2 hp VSR horizontal grinder. Ordered two small wheel attatchments and a tracking knob from Boss. And a couple other odds and ends. 4" contact/drive wheel, tracking wheel, 1/2" & 3/4" small wheels, and a locking lever from Beaumont.

You've probably guessed it by the order list. It's gonna be KMG1 meets Horizontal. It'll have a bottom mounted tool arm holder and a tool arm set-up with a SWA on both ends and a flat platen in between. Probably also go with a fixed flat platen and work rest near the drive wheel.

This way I'll be able to run with a 2x72 belt in either a 3-wheel or 4-wheel position by adjusting the tool arm and also build more task specific tool arms say for grinding integrals, plunges, or whatever else may come in handy in the future. I MAY also be able to throw on the SWA off the KMG for freehand grinding with no guards or work rests in the way or the large contact wheel (will depend on how high I can track the belt). Versatility for custom attatchments in a horizontal is my goal.

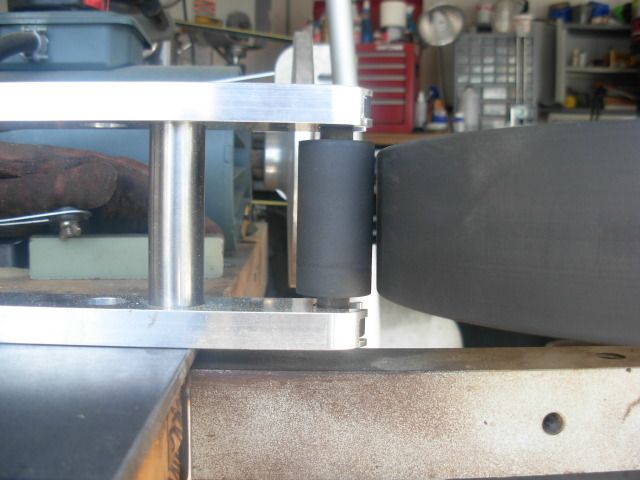

Also ordered a pair of 3/4" pillow blocks, drive shaft, and drive wheel to build a KMG buffing tool arm. The drive wheel will be situated between the pillow blocks and get power via whatever abrasive belt I happen to have on the grinder. Gonna go with quick change tapered spindles on the ends of the shaft to hold the buffs so I can easily store my buffs and compound without contamination from grinding dust. I got a 4" drive wheel to match the KMG's drive wheel so my RPM's will be variable from 3600 to zero. May not be a Baldor should function like it (I hope) For FAR less coin.

Not having access to a good scrapyard raw materials can be a little hard to come by at times so I'm going to suck it up and order a bunch of steel from online metals to build the new stuff. Before I go ordering and forget something I wanna run my list past y'all to make sure I'm not forgeting something important.

Here's my build list-

1. horizontal grinder (plates, tool arm, work rests, tracking tension arm, tool arm holder)

2. buffing attachment

3. 1 1/2" x .12 square tubing for some tool arms (and a couple spares)

4. Tool Tree for KMG attachments

5. Ray Richards Godzilla tool

6. 1/2 x 4 flat for a plunge lapping plate (Nick Wheeler style)

7. Dedicated hand sanding fixture

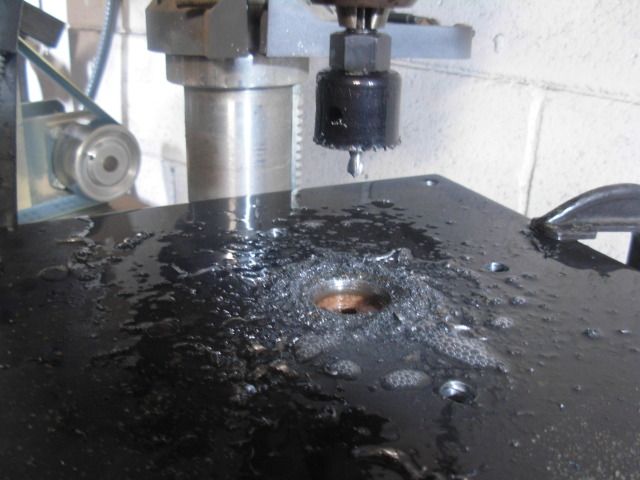

8. While I'm at it need to make a new guard press (gave the first edition to a buddy)

For now I think thats it but I wanted to ask my fellow Dogs-

WHAT AM I FORGETTING ???? That I should be building while I'm devoting time to tool construction ?

I'm all ears Fellas ! What homemade tools do use and love ? Jigs, fixtures, whatever.

Oh I am also thinking about building a nicer knifemakers vice (the one I built is fairly shoddy) and finishing the install of my caliper dro on the mill (already have the calipers too)

Thanks alot for any suggestions or ideas Dogs !

-Josh

Tax time has come again and although I'm wanting a new pistol in a bad way that hasn't over-ridden my endless need to feed the addiction :biggrin:

Tax time = TOOL time in the Dabney shop.

Rotary Platen has been ordered !:s11779:

Here's what I've got on my plate to build-

1 1/2 hp VSR horizontal grinder. Ordered two small wheel attatchments and a tracking knob from Boss. And a couple other odds and ends. 4" contact/drive wheel, tracking wheel, 1/2" & 3/4" small wheels, and a locking lever from Beaumont.

You've probably guessed it by the order list. It's gonna be KMG1 meets Horizontal. It'll have a bottom mounted tool arm holder and a tool arm set-up with a SWA on both ends and a flat platen in between. Probably also go with a fixed flat platen and work rest near the drive wheel.

This way I'll be able to run with a 2x72 belt in either a 3-wheel or 4-wheel position by adjusting the tool arm and also build more task specific tool arms say for grinding integrals, plunges, or whatever else may come in handy in the future. I MAY also be able to throw on the SWA off the KMG for freehand grinding with no guards or work rests in the way or the large contact wheel (will depend on how high I can track the belt). Versatility for custom attatchments in a horizontal is my goal.

Also ordered a pair of 3/4" pillow blocks, drive shaft, and drive wheel to build a KMG buffing tool arm. The drive wheel will be situated between the pillow blocks and get power via whatever abrasive belt I happen to have on the grinder. Gonna go with quick change tapered spindles on the ends of the shaft to hold the buffs so I can easily store my buffs and compound without contamination from grinding dust. I got a 4" drive wheel to match the KMG's drive wheel so my RPM's will be variable from 3600 to zero. May not be a Baldor should function like it (I hope) For FAR less coin.

Not having access to a good scrapyard raw materials can be a little hard to come by at times so I'm going to suck it up and order a bunch of steel from online metals to build the new stuff. Before I go ordering and forget something I wanna run my list past y'all to make sure I'm not forgeting something important.

Here's my build list-

1. horizontal grinder (plates, tool arm, work rests, tracking tension arm, tool arm holder)

2. buffing attachment

3. 1 1/2" x .12 square tubing for some tool arms (and a couple spares)

4. Tool Tree for KMG attachments

5. Ray Richards Godzilla tool

6. 1/2 x 4 flat for a plunge lapping plate (Nick Wheeler style)

7. Dedicated hand sanding fixture

8. While I'm at it need to make a new guard press (gave the first edition to a buddy)

For now I think thats it but I wanted to ask my fellow Dogs-

WHAT AM I FORGETTING ???? That I should be building while I'm devoting time to tool construction ?

I'm all ears Fellas ! What homemade tools do use and love ? Jigs, fixtures, whatever.

Oh I am also thinking about building a nicer knifemakers vice (the one I built is fairly shoddy) and finishing the install of my caliper dro on the mill (already have the calipers too)

Thanks alot for any suggestions or ideas Dogs !

-Josh