DWatson

Member

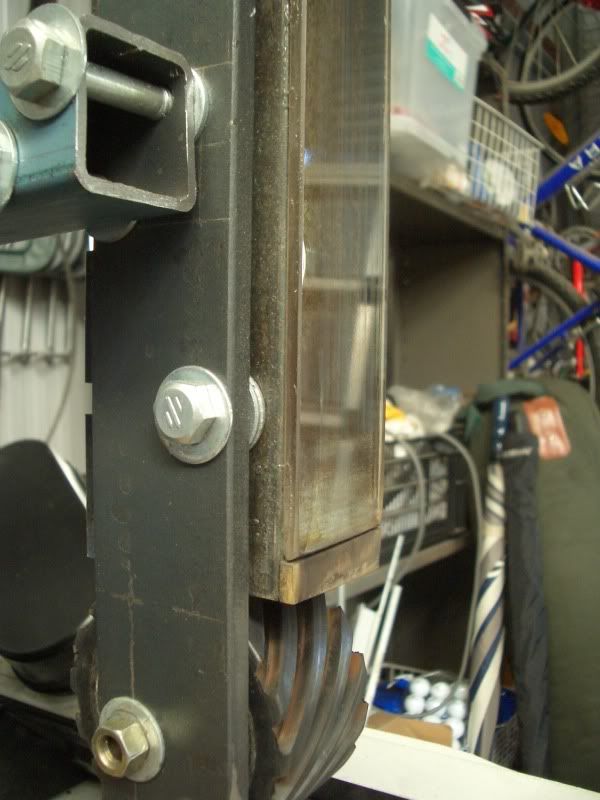

Hi everyone, just a quick question about the platen surface on a new grinder build. I am using 2x2 angle iron with slots cut out for adjustments. I am also planning to use the glass liner that Tracy sells on the front surface.

My question is, before I mount the glass, is it necessary to mount a 3/8 thick piece of steel on the angle iron, and also, is it necessary to have the surface machined for a perfect 90 degree, as it is mounted to the tool arm?

Thanks for any input.

My question is, before I mount the glass, is it necessary to mount a 3/8 thick piece of steel on the angle iron, and also, is it necessary to have the surface machined for a perfect 90 degree, as it is mounted to the tool arm?

Thanks for any input.