K R Johnson

Well-Known Member

A while back someone asked me how I install washers in shadow pattern slipjoints so here's my method.....

In this picture you can see that the milled liners and .125" black Micarta scale material are glued together. The .250" brass rod is center drilled 3/32" and on the spot on the side that's blackened with a Sharpie, I marked it with my caliper .060" from the end I faced in the lathe. I saw off two pieces for the washers just a little longer than .060".

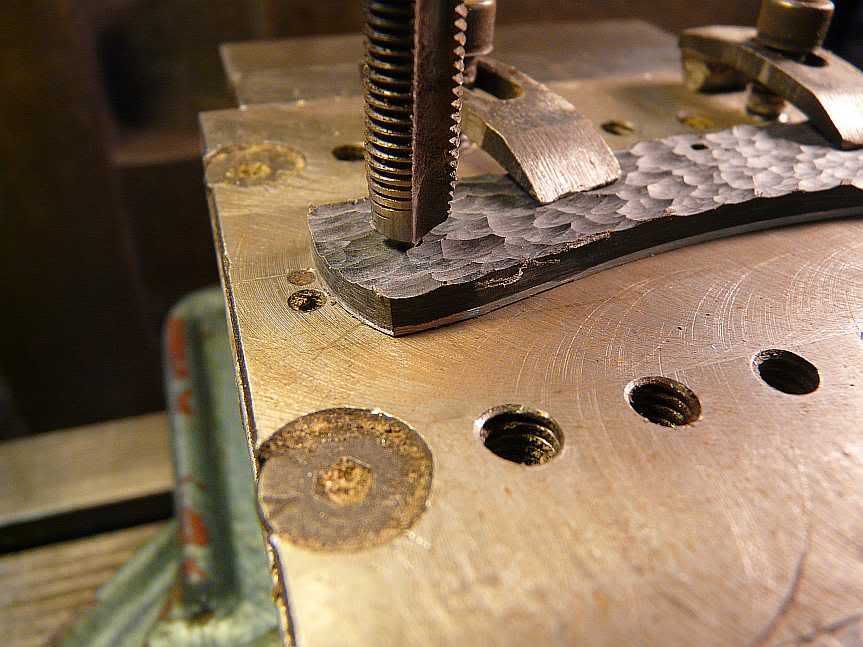

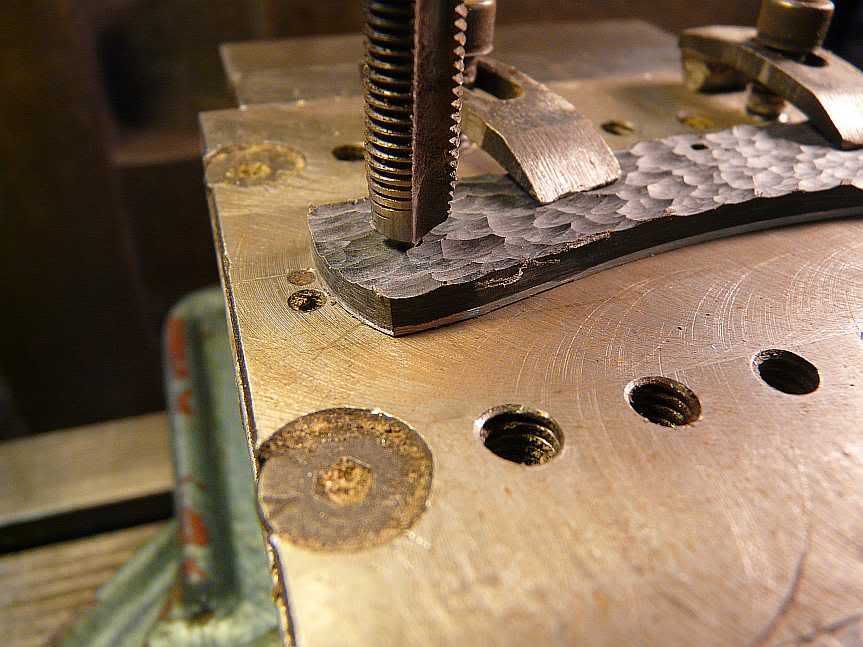

I chuck the tap in the milling machine and use the pointed end to center the pivot hole and clamp the liner and scale in place.

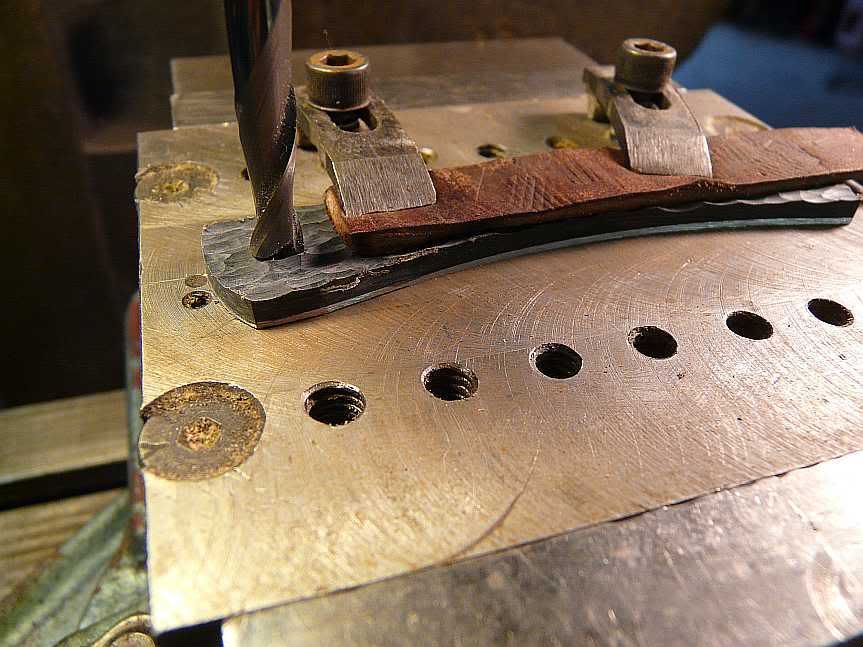

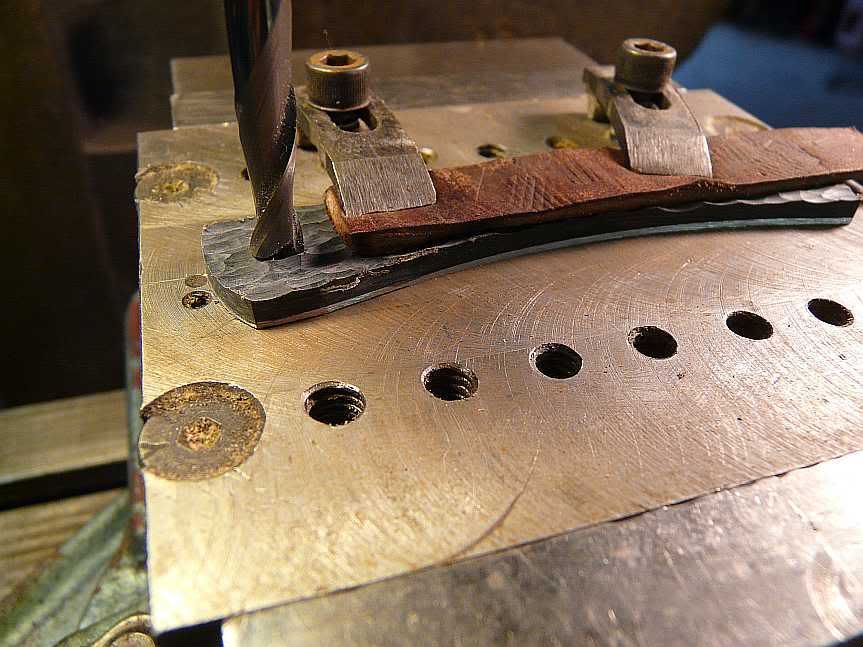

After clamping I replace the tap with a 1/4" end mill, rest the end mill on the scale and clamp the quill. I set the dial on the table at zero

and mill a pocket for the washer about .005" shallower than the thickness of the washers.

I then mill the other scale,

glue the washers in place with Loctite 330, center them again with the tap, and mill (or grind) them flush with the Micarta.

Here's how the brass washers look with a 3/32" stainless pin installed.

Additional comments:

Before cutting the washer off the rod, chamfer the edge a tiny bit, it will go in the hole easier.

I now surface grind the washers to make them the same thickness after I cut them off the rod, measure them and bore the hole to that exact depth. Glue and press them in and they'll be flush with the surface of the handle material.

In this picture you can see that the milled liners and .125" black Micarta scale material are glued together. The .250" brass rod is center drilled 3/32" and on the spot on the side that's blackened with a Sharpie, I marked it with my caliper .060" from the end I faced in the lathe. I saw off two pieces for the washers just a little longer than .060".

I chuck the tap in the milling machine and use the pointed end to center the pivot hole and clamp the liner and scale in place.

After clamping I replace the tap with a 1/4" end mill, rest the end mill on the scale and clamp the quill. I set the dial on the table at zero

and mill a pocket for the washer about .005" shallower than the thickness of the washers.

I then mill the other scale,

glue the washers in place with Loctite 330, center them again with the tap, and mill (or grind) them flush with the Micarta.

Here's how the brass washers look with a 3/32" stainless pin installed.

Additional comments:

Before cutting the washer off the rod, chamfer the edge a tiny bit, it will go in the hole easier.

I now surface grind the washers to make them the same thickness after I cut them off the rod, measure them and bore the hole to that exact depth. Glue and press them in and they'll be flush with the surface of the handle material.

Last edited: