You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making spring for lockback folder.

- Thread starter cdunn

- Start date

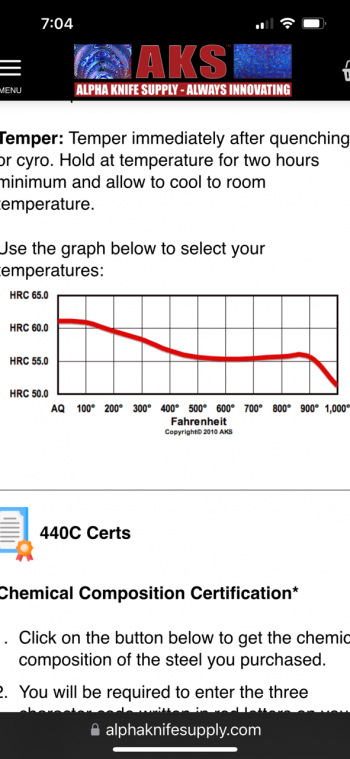

Since around 45 to 50 Rc is considered good for a slipjoint backspring - or so I've been advised for several well know slipjoint makers. I'd expect about the same for a lockback spring - does that sound ok? For AEB-L or 14C28N I normally temper around 1100°F or so and don't bother with cyro or freezer. Just from oven to quench plates.

opaul

Well-Known Member

Same here.Since around 45 to 50 Rc is considered good for a slipjoint backspring - or so I've been advised for several well know slipjoint makers. I'd expect about the same for a lockback spring - does that sound ok? For AEB-L or 14C28N I normally temper around 1100°F or so and don't bother with cyro or freezer. Just from oven to quench plates.

Thank you for the information on heat treating lock back SPRINGS, most people i deal with like interlocks or frame locks so I haven't made a back lock in a good while. I can always count on you guys from Knife Dogs for the best information.Same here.

LINERLOCKS (sorry twice, my goodness)Interlocks (sorry)

You can place the spring directly on the oven shelf or in a metal container for easier handling. Make sure the container material can withstand the high temperature. Soak the spring at this temperature for 15-20 minutes per inch of thickness. For a thin spring, this might be 5-10 minutes.