Jason Wilder

Well-Known Member

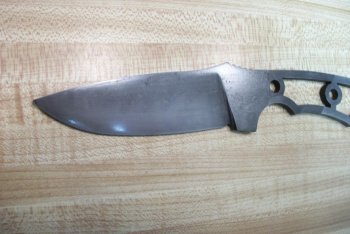

I am wanting to do a run of several kitchen knives. Not that I have any particular fondness of them, but it is one way to make a knife without feeling compaled to make a blasted sheath.

Aldo has both 52100 and 1095 ground to .110/.120 in stock and I'm on the fence as to which to get.

I know that 52100 is on high demand right now but also know that 1095 has been a go to steel for kitchen knives for decades.

52100 may be a bit more corrosion resistant, but 1095 can produce a hamon

Both require exact temps to HT but there seems to be less steps involved with 1095

Is there anything I'm missing?

Thanks,

Jason

Aldo has both 52100 and 1095 ground to .110/.120 in stock and I'm on the fence as to which to get.

I know that 52100 is on high demand right now but also know that 1095 has been a go to steel for kitchen knives for decades.

52100 may be a bit more corrosion resistant, but 1095 can produce a hamon

Both require exact temps to HT but there seems to be less steps involved with 1095

Is there anything I'm missing?

Thanks,

Jason