funkyjedi

Well-Known Member

Hey guys (and gals)!

Hey guys (and gals)!Well, I made (what would have been) a gorgeous bowie/fighter for my best friend out of a piece of .25 x 2: 1075 I got from Jantz years ago. I read that 1075 can also be made to have a hamon. I decided to give it a shot. I read for days, checked the fung shui in my shop, gathered the proper equipment and went to town.

I used rutland fire mortar for my clay, put it in the ht oven and took it to 1500 for about 10 minutes. I read that a shorter blade like a small bowie would be fine water quenching. I don't have parks 50, or any other kind of quench specific oil, as I typically just use canola, so I got the tap water as hot as I could and once the blade was ready, dropped it in and agitated it in short slicing movements to (hopefully) minimize the vapor jacket.

After about 20 seconds in the water, I heard and felt two distinct cracks. Kind of like an ice cube in a fresh glass of water.

Sure enough, I ground off the scale, and there staring me straight in the face were 3 ugly little splits. The blade also warped slightly to one side.

My guess is I should have used the oil? I've put 20+ hours into this thing and my heart broke. I almost swore off making knives.

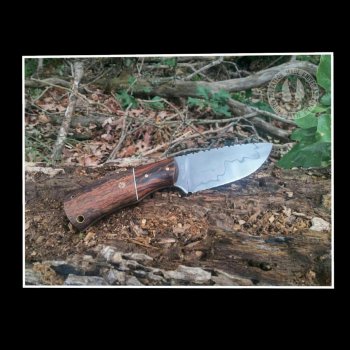

I decided, what the heck and semi-polished and etched one side of the blade to see what the hamon would have looked like.... Ill post that here. It was there alright, much to my chagrin.

If you've gotten this far, maybe you can give me some advice. I am at a loss. According to MULTIPLE threads I read, hot water should have been fine for a smaller (11" over all, 6" blade) knife.

thanks in advance.

chris

Last edited: