Self Made Knives

Well-Known Member

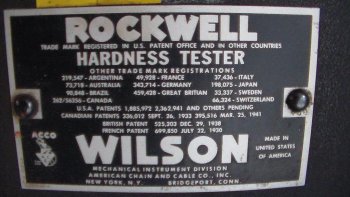

Unloaded it last night, and did I say this thing is heavy? Looking though the little book that came with it and it appears this is the tallest or widest throat of all the models. Guess that explains the weight somewhat.

At first, I had a sinking feeling, I didn't think it worked. After I few minutes of panic reading and studying, I realized what the extra weights were for, I only had one of them on the hanger. Realized that all 3 are supposed to be on it for the C scale. Whew! Put a test block on and rechecked it.

Can't get much better than that! I had a box of extras. A few test blocks, all 4 original anvils, some extra points, and 3 little pouches. One little pouch has some tiny tools in it, not sure what they're for though?

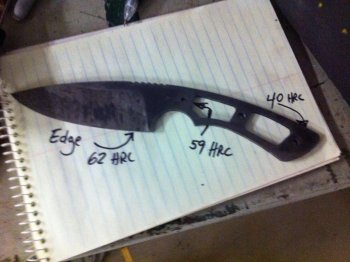

Gonna try it on some knife steel tonight, got two I need to heat treat.

At first, I had a sinking feeling, I didn't think it worked. After I few minutes of panic reading and studying, I realized what the extra weights were for, I only had one of them on the hanger. Realized that all 3 are supposed to be on it for the C scale. Whew! Put a test block on and rechecked it.

Can't get much better than that! I had a box of extras. A few test blocks, all 4 original anvils, some extra points, and 3 little pouches. One little pouch has some tiny tools in it, not sure what they're for though?

Gonna try it on some knife steel tonight, got two I need to heat treat.